Overview

With the endless innovation in consumer electronics and devices, manufacturers always seek ways to make products smaller, faster, and more reliable. This drives the need for highly compact and efficiently assembled printed circuit boards. One technology that enables this advanced PCB production is surface mount technology (SMT). SMT is an automated assembly method where components are directly mounted onto the surface of a PCB without through-hole connections. As a leading quick-turn PCB fabrication and turnkey PCB assembly service provider in China, JHYPCB utilizes cutting-edge SMT lines to deliver high-quality boards with maximum efficiency.

Unlike conventional through-hole assembly, where components are inserted into holes drilled in a PCB, SMT offers significant speed, density, and reliability advantages. By switching to SMT assembly, you can achieve faster production with smaller and more robust PCBs. Your end products can be smaller, lighter, and more feature-packed while benefiting from automated and consistent assembly.

In this blog, we will explore the key benefits of SMT PCB assembly and how it can help you meet the needs of modern electronic designs. Whether you require fast prototype runs or mass production, SMT provides advantages over through-hole assembly. Learn how SMT PCB manufacturing enhances efficiency, density, reliability, and cost-effectiveness.

What is Surface Mount Technology?

During the 1970s and 1980s, automation began to rise for PCB assembly. Traditional components with leads weren’t easy for PCB assembly. Instead, resistors and capacitors needed to possess pre-formed leads so they may fit through holes. Although this was the popular method, it had been a difficult approach to master. Leads often fail to hear the holes because they are very compact, slowing down the printed circuit board assembly procedure and raising manufacturing prices. Thankfully, surface mount technology was born. Instead of having to wire between two points, SMT components are set onto a board and then soldered to that. Their leads shouldn’t undergo any holes as required during a traditional leaded component.

Surface-mount technology was originally called “planar mounting” and was first employed by IBM in the ’60s to style small-scale computers. This technology was eventually adopted for guidance systems within the program and has been constantly improving since. SMT produces electronic circuits where the components are directly mounted onto the PCBs. Surface-mount devices (SMDs) are the result. This technology modifies through-hole using wire lead chip assembly. Many components for SMTs, often cited as surface mount devices or SMDs, are smaller and lighter than their counterparts because they need short pins, and smaller leads (or no leads at all).

Surface Mount Technology is an element of the electronic assembly that deals with mounting electronic components to the surface of the PCB. Electronic components mounted in this manner are called SMD. SMT was developed to attenuate manufacturing costs while efficiently using PCB space.

Faster SMT PCB Assembly Speeds Up Production

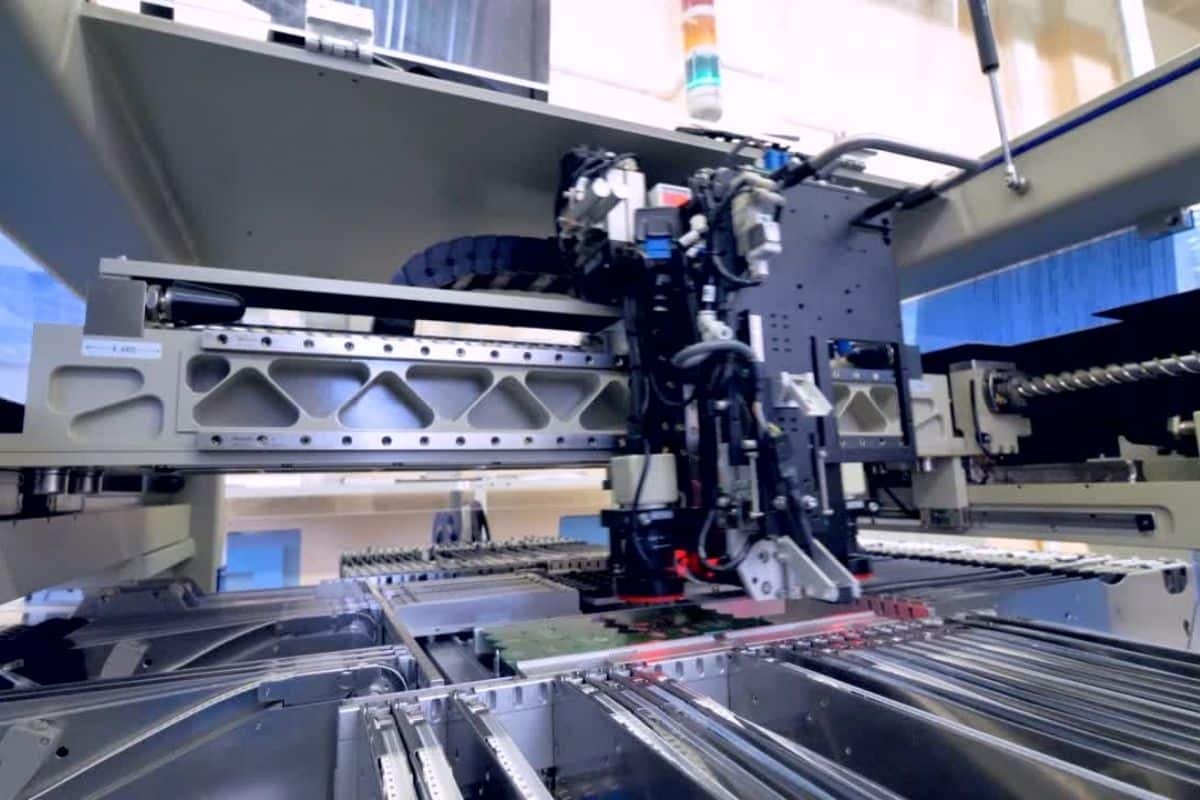

One of SMT technology’s biggest advantages is its faster assembly speed compared to conventional through-hole PCB assembly. SMT placement of components onto PCBs is an automated process, enabling entire circuits to be populated in a single pass.

Specialized pick-and-place machines precisely select surface mount components from reels or trays and rapidly place them onto solder pads on the PCB’s surface. This takes a fraction of the time needed for manually inserting through-hole components. Each part must no longer be inserted separately by hand, which is tedious and time-consuming.

With SMT assembly, hundreds or thousands of parts can be placed per hour. This is perfect for high-volume production needs where speed and efficiency are critical. Automated optical inspection after SMT component placement also catches any defects early.

By transitioning your PCB assembly process to utilize SMT, you can slash overall manufacturing times compared to manual through-hole assembly. This accelerated schedule gets your innovative products to market faster to stay ahead of the competition. The quick turnaround of SMT lines also makes them ideal for fast prototyping during the design stage.

At JHYPCB, our advanced SMT lines are capable of incredibly fast setup and changeover between runs. This enables us to assemble even small batch orders rapidly, so you get your prototype PCBs delivered with minimal lead time. For production needs, SMT will significantly cut down total assembly time so you meet delivery demands.

SMT Components Take Up Less Space for Denser PCBs

Another major benefit of surface mount technology is the small size of SMT components compared to their through-hole counterparts. This allows fitting much higher densities of components onto the same PCB footprint.

Instead of dangling legs that need to be inserted into holes, surface mount parts have tiny metallic pads that solder directly to the surface of PCBs. Typical SMT components include small plastic packages, flat chips without cases, and tiny chip-scale packages.

Using these miniature surface mount components, PCB assembly with SMT enables far more compact product designs. A PCB assembled with SMT can pack in 5 to 10 times the component density of a traditional through-hole populated board.

Higher-density component mounting provides numerous advantages. End products can be made smaller and lighter when you switch to SMT PCB assembly. More functionality and features can be integrated into the same constrained space. This miniaturization is critical for the latest consumer gadgets, IoT devices, wearables, and other electronics where small size is desirable.

SMT PCB manufacturing also allows for keeping signal traces shorter. With components placed close together, electrical paths are minimized. This optimizes high-speed signal performance in space-constrained high-tech products.

JHYPCB’s SMT assembly lines accommodate the full range of component packages down to 0201 chips just 0.6mm x 0.3mm in size. We have the precision mounting capabilities to assemble ultra-dense PCBs with SMT, allowing you to make your products as compact as possible. Utilize our SMT services to manufacture advanced, miniaturized PCB designs.

Improved Reliability from SMT Component Mounting

In addition to faster assembly and higher-density PCBs, surface mount technology provides reliability enhancements over through-hole mounting. The automated process and small size of SMT components result in very robust solder joints.

Since precision pick-and-place machines perform SMT placement, the components are soldered with consistent accuracy. Solder joints are uniform in shape and size with minimal variances across a single board or between boards in a production run.

This ensures strong, reliable connections between the components and PCB pads. In comparison, the manual through-hole assembly can lead to inconsistencies as workers manually solder each joint, varying quality between operators.

The small contact area between SMT components and PCBs also makes the solder joints less susceptible to failure from shocks, vibrations, and temperature swings. Through-hole parts with long dangling legs are more prone to joint damage as the board is shaken.

SMT PCB assembly enhances reliability through extensive inspection capabilities too. Automated optical inspection (AOI) systems quickly scan boards after the SMT population, identifying any missing, misaligned, or defective components that could affect function.

At JHYPCB, all our in-house assembled boards undergo rigorous AOI checking and testing. This quality control ensures each board meets the highest assembly performance and durability standards expected from SMT production.

By leveraging SMT assembly for your next project, you benefit from the precision and consistency of automated component mounting. Your end product will deliver improved reliability and withstand challenging operating environments.

Lower Costs with SMT PCB Assembly

While the upfront capital investment for SMT equipment is substantial, surface mount technology provides significant cost reductions compared to through-hole assembly in the long run.

The automated nature of SMT lines heavily reduces labor requirements for the PCB population. Instead of relying on large teams of manual operators, just a small staff is needed to run SMT pick-and-place machines. For very high-volume production, SMT assembly can even be nearly fully automated.

Additionally, SMT components themselves cost less than equivalents sized for through-hole insertion. Mass manufacturing using reels and tapes reduces part costs. And tiny chip components used in SMT are cheaper at scale compared to bulky through-hole parts.

Higher component density with SMT allows further cost savings, too. By shrinking PCB size through greater miniaturization, fewer board materials are consumed. You also save on the enclosure, cables, and other physical elements around the board.

Once volume production ramps up, these cost benefits are multiplied dramatically. JHYPCB provides complete turnkey SMT services so you can realize lower assembly costs, even from your prototype builds. We scale flexibly up to high-volume manufacturing.

Our large SMT factory in China gives us access to an extensive component supplier base with competitive pricing. These cost savings are passed on to customers. JHYPCB also offers PCB fabrication, component sourcing, enclosure manufacturing, and full product assembly all under one roof.

Achieve Faster, Denser, and More Reliable PCBs with SMT

Surface mount technology assembly brings transformative advantages to PCB manufacturing. By utilizing SMT instead of through-hole assembly, you benefit from:

- Faster automated placement of components for reduced PCB population times

- Smaller surface mount components enable increased board density

- Improved reliability from consistent solder joints and rigorous inspection

- Lower costs through automation, part miniaturization, and economies of scale

SMT is the ideal choice for assembling high-tech products where small size, quick assembly, and ruggedness are key. It is especially suited for consumer electronics, IoT devices, industrial equipment, telecom hardware, automotive electronics, and aerospace systems.

As a full-service PCB company based in China, JHYPCB offers a complete range of SMT assembly capabilities. Our highly automated lines can quickly assemble SMT boards with the highest quality and lowest cost, from prototyping to volume production.

We also provide PCB fabrication, layout design, component sourcing, and complete product manufacturing and testing services. Our one-stop solution simplifies bringing your innovative electronic designs to reality.

Contact us today to learn how our advanced SMT assembly services can manufacture your next-generation PCBs. JHYPCB helps forward-thinking engineers, designers, and companies build electronics better and faster using surface mount technology.