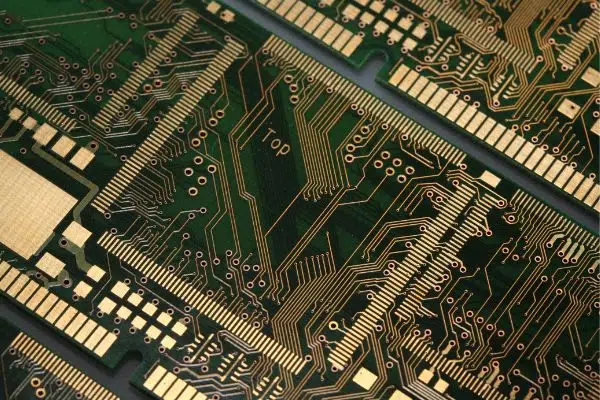

PCB Manufacturing Services

Flexible PCB Fabrication Service

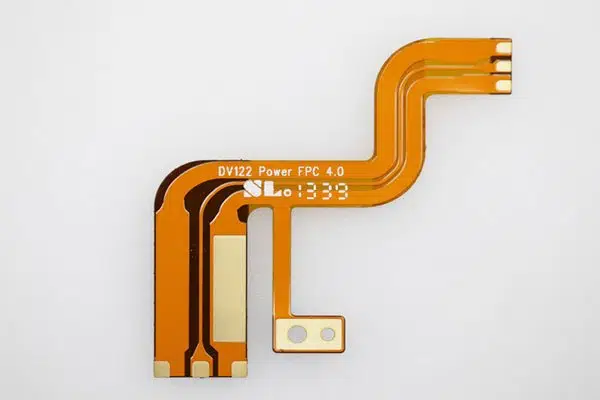

A flexible Printed Circuit (FPC for short) is a highly reliable printed circuit board made of polyimide or polyester dielectric film clad with rolled copper.

JHYPCB

Flex PCB Manufacturing

What is Flex Circuit Board?

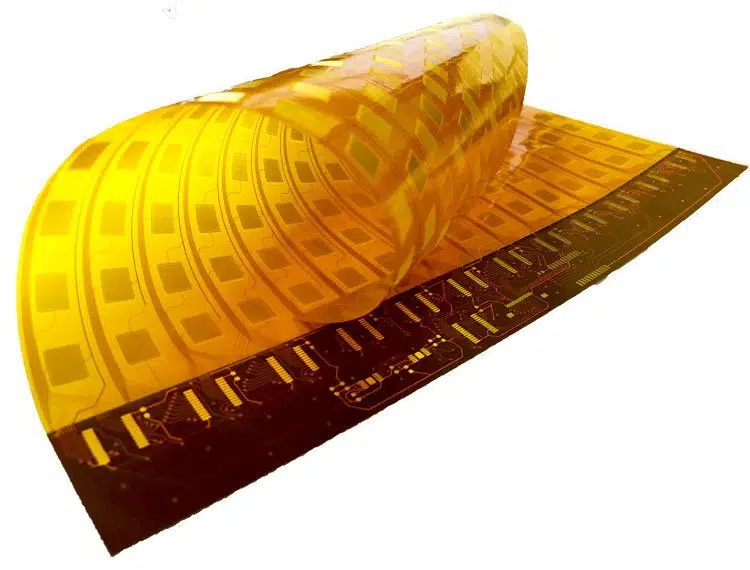

Flexible printed circuits, also called flex circuits, are sometimes considered printed circuit boards (PCBs) that will bend, when in point of fact, there are significant differences between PCBs and flex circuits when it involves the design, fabrication, and functionality. One common mistake designers make is to style a versatile circuit using the same rules as a PCB. Flex circuits require a singular set-up and have their own design rules that the JHYPCB team has termed “flex-sizing” and have worked hard to perfect over the last 10+ years. The word “printed” is somewhat of a misnomer as many manufacturing processes today use photo imaging or laser imaging because of the pattern definition method instead of printing.

A flexible printed circuit consists of a metallic layer of traces, usually copper, bonded to a dielectric layer, usually polyimide. The thickness of the metal layer is often skinny (<.0001″) to very thick (> .010″), and therefore the dielectric thickness can vary from .0005″ to .010″. Often an adhesive is employed to bond the metal to the substrate, but other varieties of bonding like vapor deposition will be wont to attach the metal. Because copper tends to readily oxidize, the exposed surfaces are often covered with a protective layer, gold or solder are the 2 commonest materials thanks to their conductivity and environmental durability. For non-contact areas a dielectric material is employed to guard the circuitry against oxidation or electrical shorting.

The number of fabric combinations that might enter a versatile printed circuit is nearly endless; current, capacitance, chemical and mechanical resistance, temperature extremes, and kind of flexing are just a few of the standards that impact the fabric selections that best meet the functional needs. An experienced JHYPCB design engineer takes the critical requirements into consideration when designing a circuit to satisfy your needs.

Flexible Circuit Fabrication

Flex Circuit Manufacturing Process

There are two basic categories of processes for manufacturing a versatile printed circuit: Subtractive and Additive.

Subtractive

In a subtractive process, one starts with a solid area of metal, and therefore the unwanted areas of metal are removed to create the traces. Screen printing and photo imaging are the 2 commonest processes used for outlining the circuitry pattern.

Additive

In an additive process, one starts with a bare dielectric layer, and also the metallic traces are added only where needed to make the circuit. The conductive layer may be printed, plated, or deposited in an exceeding form of manners.

The subtractive processes are far more common thanks to being more robust, cost-effective, and permit greater choices in final product configuration. The circuits created by the additive process have less current carrying capability and environmental resistance than circuits created by the subtractive processes.

Flex Circuit Finishing and Assembly

Surface finishing is sometimes required to assure the printed circuit surface is prepared for subsequent bonding like SMT assembly, wire bonding, or pressure connector insertion. Nickel/gold, tin, silver, and solder are excellent metals for this purpose. Organic coatings also can be accustomed to protect the copper until the bonding process where the fabric is dissolved away as a part of the method.

There are countless assembly options for a versatile printed circuit. Additionally, to electronic components and connectors, a spread of electrical or mechanical devices may be attached to a versatile circuit. The circuit also can be easily bonded to a curved surface or formed in any 3-dimensional shape. With proper construction a flex circuit can handle dynamic flexing, making it the best interconnect solution for electronic packages that connect moving or rotating parts.

Flexible Printed Circuit Design Advantages

The fact that flex will be bent, folded, and configured in barely about any shape or thickness imaginable gives the designer tremendous options when creating an electronics package. Size and space limitations are far less of a problem than a traditional design using hardboard circuits. Assembly and handling costs may be significantly decreased because the whole interconnect system is often built in mutually integrated part. Add JHYPCB’s ability for component assembly and testing and therefore the supply chain management becomes greatly simplified. This tremendous flexibility in design choices ends up in electronic packages being smaller, lighter, and more functional.

Types of Flex Circuit Board

There is a wide range of circuitry configurations, sizes, and functionality, but flex printed circuits can be categorized as one of the following types.

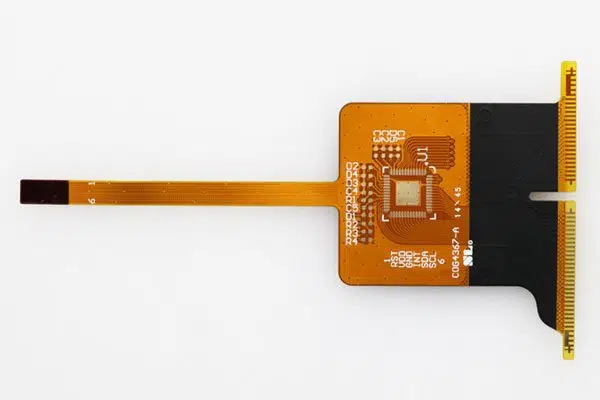

Single-Sided Flexible Circuit

Single-sided flexible circuits are ideal for various situations, including unusual folding, forming, or dynamic applications. Consisting of one copper-conductor layer on a versatile dielectric film, single-sided flexible circuits provide a singular variety of printed circuit boards for installation or service flexing. Single-sided flexible circuits are fabricated with or without cover layers.

Learn more about what single-sided PCB is?

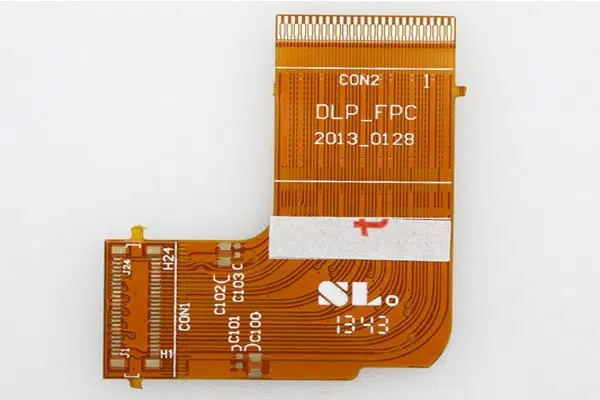

Double-Sided Flexible Circuit

Double-sided printed flex circuits give designers another level of capability for more complex applications. When an application implies a high-density design and layout, double-sided printed flex circuits ensure a compact, efficient design ideal for such uses as ground and power plane applications. Double-sided flexible circuits may also be commonly found in shielding applications or on a dense surface-mount assembly.

Learn more about what double-sided PCB is?

Multi-Layer Flex Circuit

Several copper layers are separated and encapsulated by dielectric layers. Metal layers are connected by metalized through-holes.

Learn more about what multilayer PCB is?

A rigid-flex board is a mixture of a rigid board and a flex circuit. The flexible coatings are sandwiched between two rigid boards using no-flow prepreg. This kind of flex performs well when there are parts on both the top and bottom sides. This is a multi-layer circuit where a number of the layers are hardboard and a few are flexible circuitry. These are used when components are mounted on either side of the rigid section.

Flex Circuit Manufacturer In China

JHYPCB is the world’s premier Printed circuit board manufacturing and assembly supplier in Shenzhen, China, providing excellent flexible PCB prototyping, multi-layer PCB manufacturing, and PCB assembly services. Our superb flexible PCB manufacturing capabilities can meet your complex requirements.