PCB Assembly Testing and Inspection Services

PCB Assembly Inspection

PCB Assembly Inspection Service

For quality assurance, PCB Assembly inspection is another process we carry out at JingHongYi PCB (HK) Co., Limited. This is one of the reasons why we remain the best among other PCB assembly and manufacturing suppliers. There is no doubt that we will inspect your circuit boards to ensure they are up to the required standard.

PCBA Inspection Service

What Is PCBA Inspection?

This is a process that is carried out to check whether your circuit boards have any fault that will hinder them from performing optimally. It is not enough to hire a company for PCB assembly. Rather, it is also necessary that such boards are inspected whether there are any possible defects.

The best part is that at JingHongYi PCB (HK) Co., Limited, we are not just about PCB assembly and manufacturing. This is because we also understand how to carry out the most modern and advanced inspection procedures.

What Are The Common PCB Assembly Defects?

Talking about defects, there are different types that we are always looking out for. These are:

- Component shift

- Lifted pad

- Cold joints

- DFM errors

- Incorrect PCB footprints

- Open solder joints

- Solder bridges

- Webbing and splashes

- Excess shoulder

- Placement and misalignment

- And more

Given these types of defects, it is not possible for your circuit boards to function as expected.

What Are The Benefits of PCB Assembly Inspection?

It doesn’t really matter the PCB manufacturing and assembly company that is handling your project. This is because one thing is always certain – occurrence of errors. When such happens, your circuit boards are likely to malfunction or even crash during usage. This is one of the reasons why most electronic appliances and devices do not stand the test of time.

Their circuit boards were not inspected during the early stages when they got manufactured. This is what PCB assembly inspection is all about. It helps in ensuring there is no issue related to circuit boards malfunctioning. Apart from defects, this process can ensure circuit boards are optimized for better functionalities. Finally, PCB inspection avoids a situation whereby products are sent to customers and then returned due to being poorly manufactured.

What Are The Methods of PCB Assembly Inspection?

JingHongYi PCB (HK) Co., Limited is a trusted company when it comes to adopting the best PCB assembly inspection methods. In fact, our methods are reliable, objective and 100% result-oriented. These will be explained below.

This is more like a visual inspection which tries to look at aspects such as solder paste, components, and bare boards of PCBs.

This involves inspecting a few boards (1-5) from those that have been mass produced. It is all about verifying the process through which such boards have been produced.

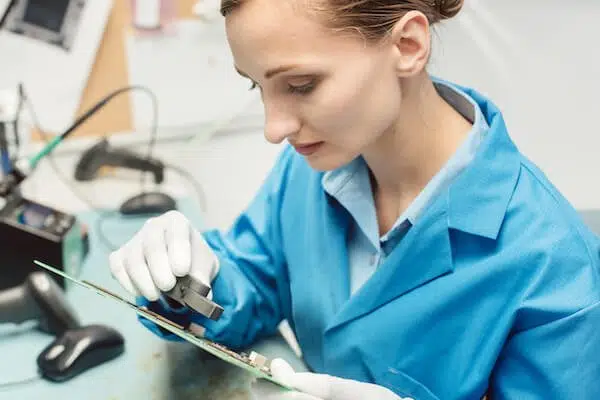

In this process, the circuit boards will be inspected in a bid to spot defects. A magnifying glass is usually used for this process.

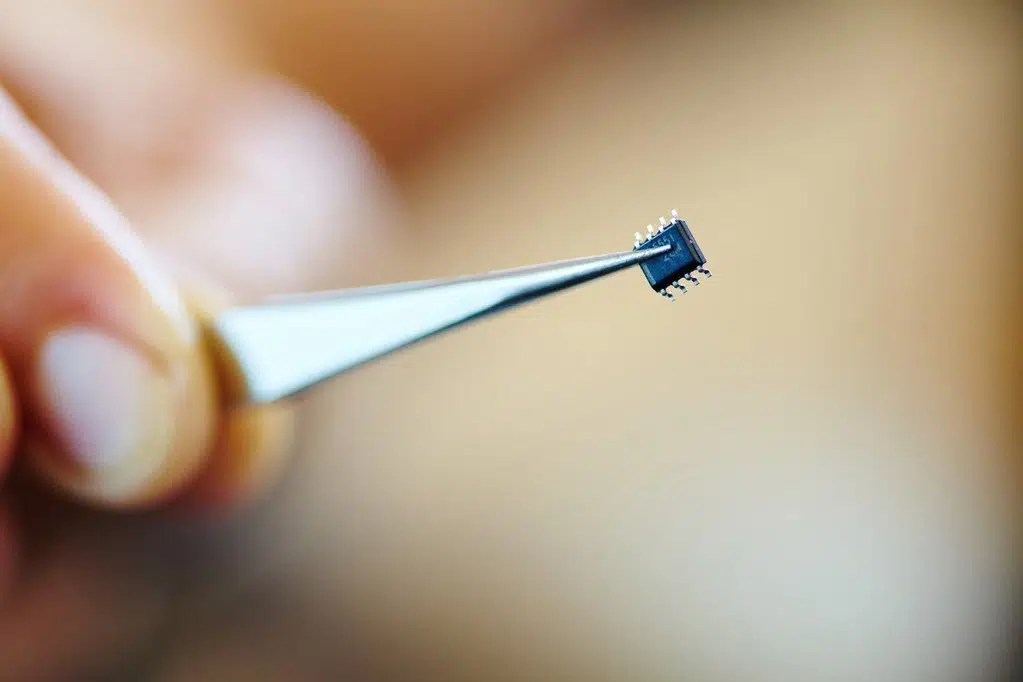

This involves the circuit board being scanned for defects like component skew, fillet size or shape. It can be used in finding missing components that are likely to cause failure.

In this case, an x-ray is used in inspecting the features of a printed circuit board. It tends to have access to features that are not visible. It could be scanning of solder joints for PCB components or checking other features.

This is a specialized process which tends to investigate the quality solder paste that has been deposited on circuit boards. Its goal is to ensure the right solder paste has been used.

This inspection will be carried out prior to when the PCB assembly and manufacturing processes become completed.

This inspection is carried out to ensure the board has passed all the necessary manufacturing tests.

This inspection will be carried out to ensure the shipping standards for your circuit boards are in line with what you have specified. It is the final stage of PCB assembly inspection.

Related Reading

- How to Choose a PCB Assembly Manufacturer?

- Why Choose China PCB Assembly Manufacturer?

- What are the Advantages of a Prototype PCB Assembly?

- What are the Benefits of Turnkey PCB Assembly?

- Small Batch PCB Assembly Essential for Prototyping

- SMD Vs. SMT, what is The Difference?

- How to Reduce Your PCB Assembly Cost?

- What are the Benefits of SMT PCB Assembly?

- Ultimate Guide To PCB Assembly Testing Service