PCB Assembly Inspection Services

X-Ray Inspection

The Importance of X-ray Inspection in PCB Assembly

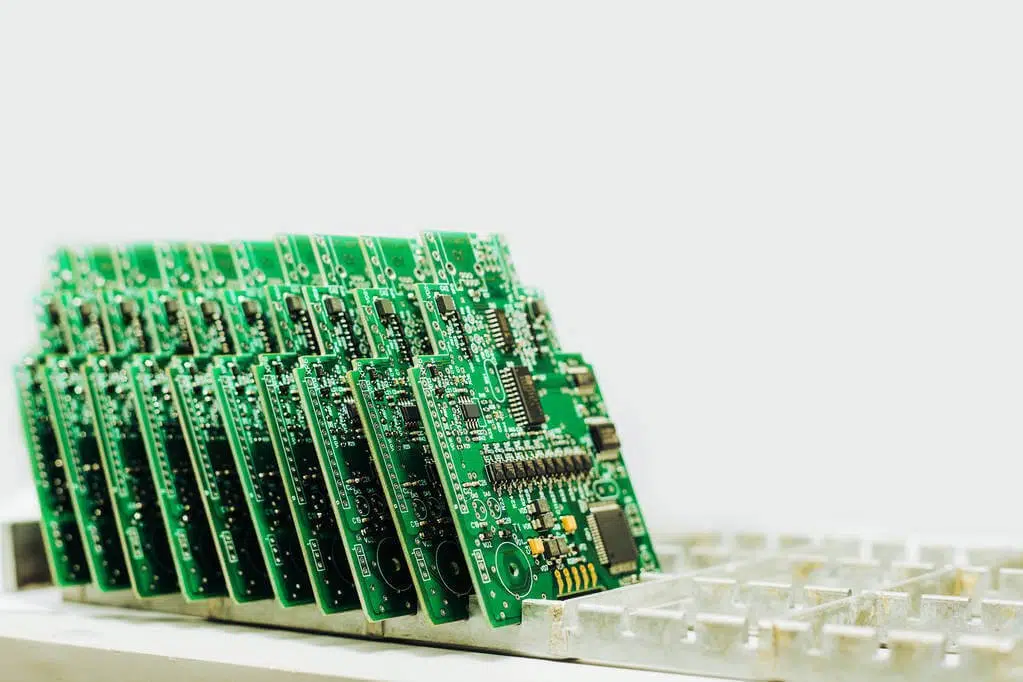

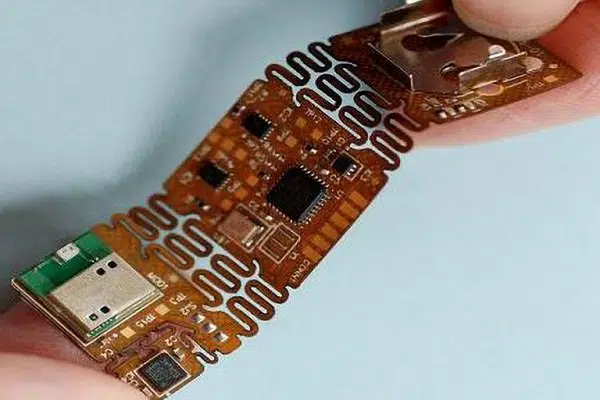

JHYPCB maintains a quality-oriented and standardized approach when it comes to the x-ray inspection of PCB fabrication and PCB assembly. As part of our quality control and assurance procedures, we usually execute industry-approved and recommended tests and inspections. We do not tolerate defective or substandard products. Due to this, we offer various analytical testing solutions which help us to detect possible defects in any part of the PCBs. Our inspection services include X-ray inspection, solder paste inspection(SPI), Automated Optical Inspection (AOI), First Article Inspection (FAI), and visual inspection. We carry out these inspection services to help us troubleshoot and repair various defects. We have a workforce that is highly trained and can help with your project.

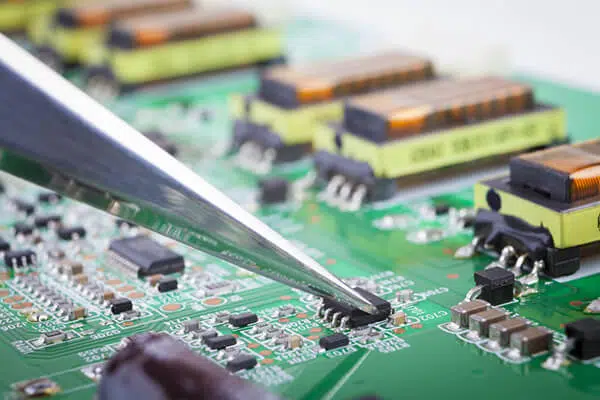

At JHYPCB, our X-ray technology has been designed basically to be used for the inspection of printed circuit boards. The technology can be used to check the integrity of solder joints that have been made on newer PCB components and electronic packages. This technique helps us to verify and validate the quality of soldered joints in the PCBs. Conventional visible and optical inspections may not be able to provide the necessary result. This is because the joints may be embedded within the body of the component or buried beneath the surface.

Our x-ray inspection machine is also equipped with a special tilt function. This way, we can view the joints from an oblique angle. This way, we can easily identify the defective solder joints.

One reason that x-ray inspection is so useful in the PCB industry is its “non-destructive” nature. This means that we can check all PCBs without affecting their performances. This quality is useful for controlling and validating the quality of the PCBs.

PCB Assembly Testing & Inspection Service

Getting Quality X-ray Inspection Service from JHYPCB

JHYPCB is a leading PCB manufacturing and assembly supplier in China, known for providing high-quality PCB manufacturing and assembly services.

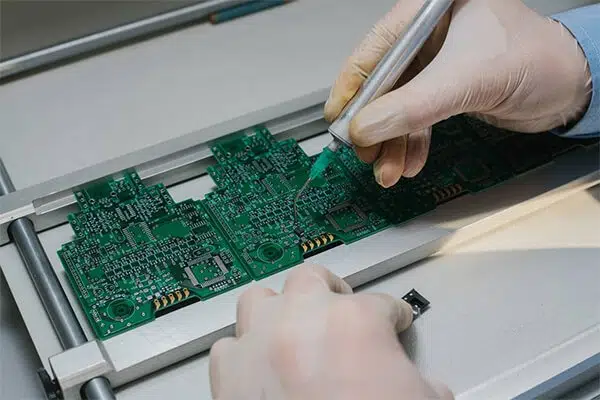

JHYPCB is a modern company that provides quality and standard X-ray inspection services. This inspection routine is a massive part of our quality control processes. It makes use of a special technology that can be used to reveal any hidden defects in a target PCB. We apply X-ray inspection to help us to detect possible defects among PCBs that have been manufactured and assembled. Our X-ray inspection services offer a lot of benefits and opportunities for all types of printed board circuits. Our unique X-ray inspection services are very suitable for testing the quality of PCBs. This way, we can be able to easily detect any hidden defects in the PCB. Our x-ray technology is very mild on your PCB devices and will not cause any damage to your boards.

Why do we need an x-ray inspection?

Many people may be wondering if there is any need for the x-ay inspection. The x-ray inspection produces a more thorough result in comparison to many other visual inspection methods. There are certain types of PCB connections where the joints may be located at a lower level inside the components. With such PCBs, using AOI and visual testing may not be sufficient to validate the accuracy of the PCB assembly. For JHYPCB to meet strict quality control requirements, we must perform the x-ray inspection routine. We have added a sophisticated and automated x-ray inspection machine as part of our quality control tool and instrument.

Quality control guarantee through x-ray inspection:

How does it work?

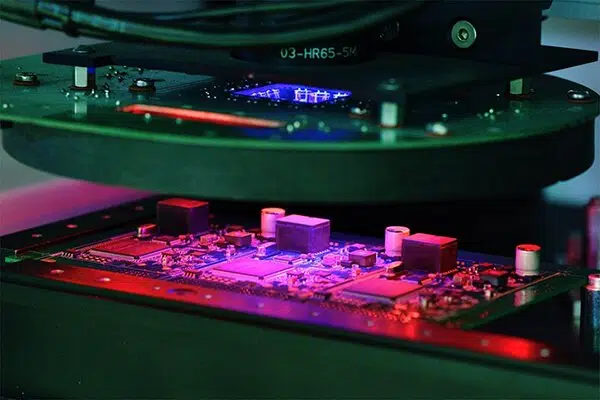

How does our X-ray inspection work?

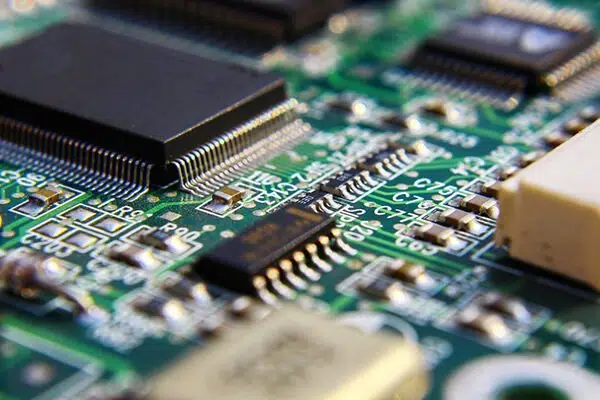

We make the x-ray penetrate through the silicon of the IC device. This way, the rays pass through the board and produces a reflection of the component just underneath the surface. This way, a clear and reliable image of the joints can be formed easily. Once we obtain this image, we use a sophisticated image processing technology to analyze the image produced by the x-ray device. There are usually higher density elements in the captured location of the image. This way, we can use quantitative analysis to detect the integrity of the soldered joints. This can then be compared against the industry requirements and standards.

The importance of our x-ray inspection goes beyond detecting PCB assembly issues. The image from an x-ray inspection can also be used to identify the underlying cause of a certain problem. Our x-ray technology can be used to look for the root causes of issues like:

- Poor reflow soldering profile

- Skewed part placement, or

- Inadequate solder paste

This is a significant technique that contributes immensely to our total quality management strategy. This way, we can check and inspect the accuracy of complex PCB components.

About JingHongYi PCB (HK) Co., limited

JHYPCB is a company that is focused on the production and supply of quality PCBs. We are based in China and cater to a wide range of global customers. Many original equipment manufacturers depend on our expertise to produce their devices. JHYPCB have been able to help many production facilities create groundbreaking electric devices because of the quality and integrity of our PCBs. When it comes to PCB assembly and manufacture in China, the only name that you can trust is JHYPCB. We are your most reliable and trusted name when it comes to quality and standard PCBs. JHYPCB is a total PCB solutions company that also performs quality PCB x-ray inspection services. Our fast turnaround time has made so many customers solicit our X-ray inspection services as part of their production projects. We provide this service to help confirm and validate that individual PCBs meet strict standards and requirements. Once all components pass through our x-ray inspection phase, they will then be packaged for shipping to the customer. We have also set up an effective and efficient x-ray inspection system for turnkey PCBA (printed circuit board assemblies. Our x-ray inspections are applicable for detecting the following:

- Soldering defects: Our x-ray inspection is useful for identifying the different problems that can affect any soldered joints in PCB components. this may be excess solder, insufficient soldering, solder bridges, solder shorts, open circuits, and so on.

- Components defects: We can easily verify different defects of various components.

- CSP and BGA defects: These are the defects that are identified from components with complex designs. Since they are evasive to normal techniques, our x-ray inspection helps us easily identify them.