PCB Manufacturing Services

Single Sided PCB Fabrication Service

A Complete Guide to Single-Sided PCBs

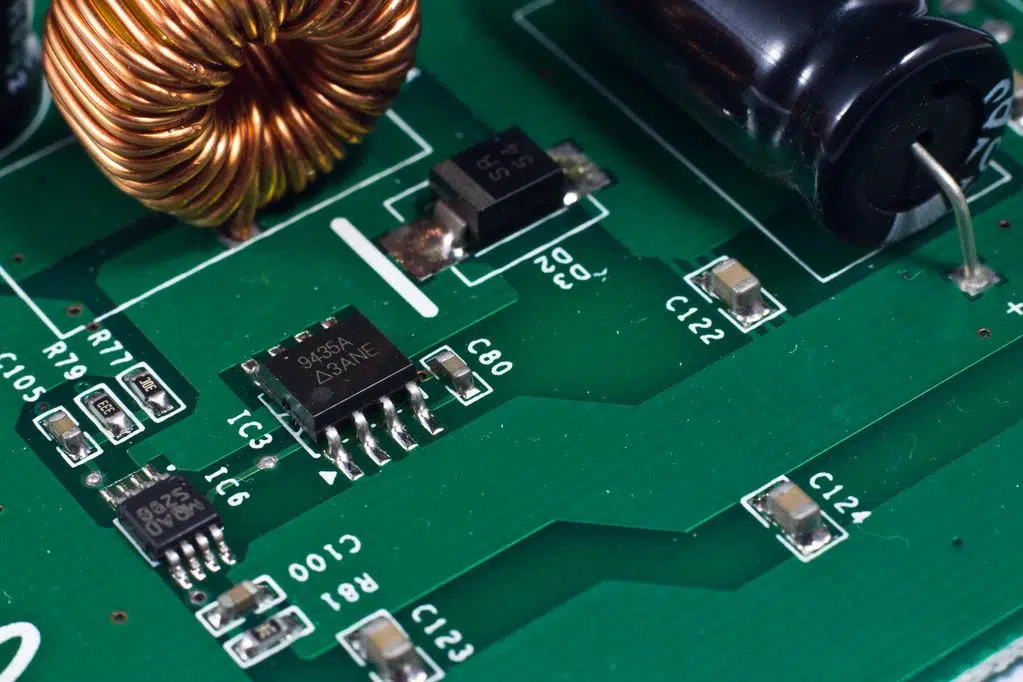

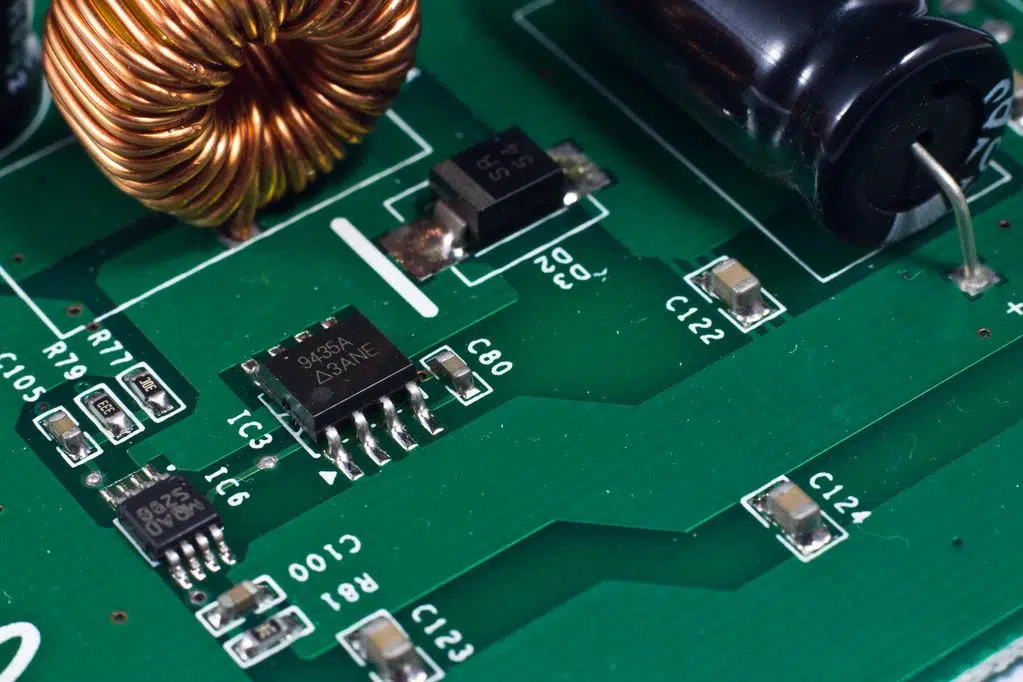

When it comes to PCBs, they’re named single-layer, double-layer, and multilayer PCBs. The number of layers in a very PCB is the number of conductive or copper layers it’s. PCBs even have other layers, like the bottom layer, a dielectric layer, solder mask, and silkscreen; however, the number of layers only represents the quantity of copper/conductive/circuit layers. Thus, a PCB with one conductive layer to make a circuit is understood as one Layer PCB.

A Single Layer PCB is that the simplest PCB as there’s just one conductive layer. It’s widely utilized in dozens of applications where we want a compact circuit. Among every type of PCBs, single-layer PCBs are preferred and also the most purchased. Designers select double-layer or multilayer PCBs when the circuit is sort of complex and can’t be implemented on a single-layer circuit. Otherwise, a single-layer PCB is the first choice for any device, product, or project.

Single-Sided PCB DEFINITION

What is a single-sided PCB?

A single-layer PCB is a printed circuit board with a simple design and a wide range of applications. Single-layer PCB boards are easy to manufacture and low in cost and are the first choice for many electronic products with fewer functions.

The word PCB stands for printed circuit board and single layer PCB is such a variety of a PCB that is printed only from one side, which means PCB sheet is printed from one side with a conductive material, on the other side electronics components are connected electrically and stuck mechanically. Before introducing the PCB sheet point-to-point construction method was accustomed make a circuit that was most difficult and was take longer with space to form a circuit. The first time single-sided PCB was made in 1950 and is still used in the market in a very bulk quantity. Different materials are used for creating single-layer PCB like optical fiber-reinforced epoxy glue with copper foil and paper reinforced phenolic with copper foil etc.

Single-layer PCB, also referred to as a single-sided PCB, could be a sort of PCB with just one layer of conducting material on one side of the board, and the other side is used for incorporating different electronic components on the board. Single-layer PCB is widely utilized in the printed circuit board design in a very sort of different electronic sectors where low costs are required. What’s more, single-layer PCB has been made from various fabrics, like paper reinforced phenolic with copper foil and fiber-reinforced epoxy with copper foil, and then on.

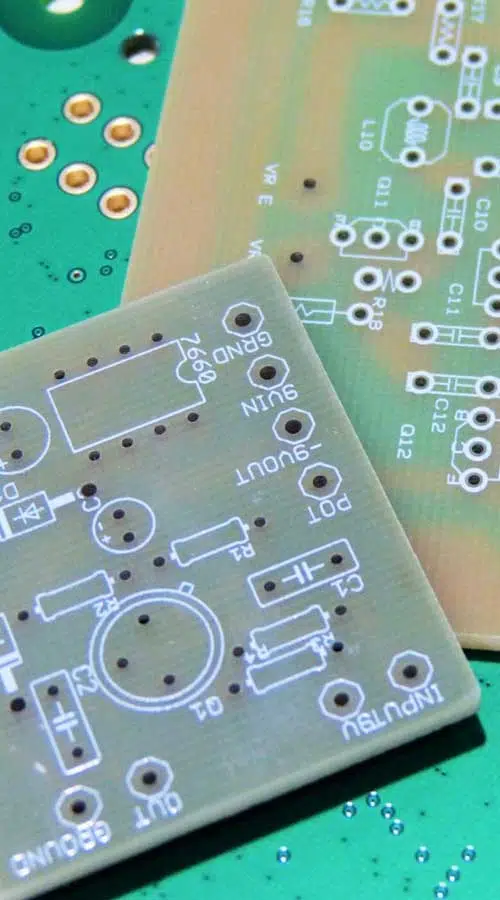

Construction of Single Layer PCB

For making a manually PCB board first design the layout of the circuit on computer software, print this on a straightforward page then iron this page on a PCB sheet. When the entire circuit is ironed on a PCB sheet then this PCB sheet is a skilled etched process. Because the highest layer of PCB sheet is fully made with a conductive material like copper therefore when it’s etched with the assistance of ferric chloride then this layer is dissolved in ferric chloride except for the printed circuit layer. After etching now this PCB sheet is prepared to insert the electronic components. But before inserting components wholes are made with a drill machine. This was the manual process for creating a PCB board but now numerous PCB machines are available in the market that does all this process automatically. In these machines, circuit layout is created with the assistance of software and so just insert the PCB sheet and component during this machine. It gives you your required design circuit. Now, creating the PCB circuit became most easy.

Types of Single Layer PCB

Some single layer PCBs are presently in use and here we shell describe them with respect to their manufacturing material.

Single Layer Rigid PCB

It is the sort of one layer PCB that’s made up of a rigid material like fiberglass. These PCBs are inflexible and stop the circuit from bending and breaking. Currently, these are used in differing types of devices, like calculators and power supplies, etc.

Single Layer Flexible PCB

It is the kind of single layer PCB, which is made out of a versatile material rather than a rigid material, and for this purpose, plastic materials are used. It’s such a large amount of advantages over single layer rigid pub, but its fabrication cost is such a lot high.

Single Layer Rigid-Flex PCB

It is the kind of single layer PCB that is used for high-frequency circuits, usually in gigahertz. These PCBs are made out of a Teflon or polyphenylene oxide (PPO) material. During choosing a high-frequency single layer PCB, many aspects are kept in mind, like dielectric loss, thermal expansion, water absorption, etc.

Single Layer High-Frequency PCB

It is the sort of single-layer PCB which is formed out of a mix of plastic and fiberglass. Both materials are combined into one layer. It’s a lot of advantages over single layer rigid and versatile PCB like it reduces the load and size of the PCB.

Single Layer Aluminum PCB

It is the sort of single layer PCB which is formed out with an aluminum material substrate. The look of this PCB is nearly identical to copper-backed PCB, but the sole difference is that in these PCBs, an aluminum substrate is used rather than copper. Aluminum-backed is used with thermal insulation for transferring the warmth from insulant to back.

Supporting Subheading

Advantages of Single Side PCB

Simple Design

The design of a single-sided PCB is sort of simple. there’s just one conductive layer, so it’s easy for the designers to form a design. There are fewer errors within the designing process, and therefore the PCB is more likely to supply the required results even within the first prototype.

Easily Available

Single-sided PCB is kind of easy to manufacture because it features a basic design. you’ll easily find a single-layer PCB manufacturer in your city or country. All PCB manufacturers offer this service, so you’ll easily order from anyone.

Low Cost

The cost of a single-layer PCB is not up to a multilayer PCB. It doesn’t require high-end pieces of machinery as in other styles of PCB. If you order in bulk, the value of the PCB is further reduced. A single-layer PCB is that the most suitable option if you wish to save lots of costs.

More Reliable

The design of a single-layer PCB is easy, so it’s more reliable. There are fewer chances of errors and faults. It offers excellent performance and high reliability. The long-lasting operation of the board and components is additionally ensured.

Easy Testing and Repairing

The testing of a single-layer PCB is simpler than a multilayer PCB. The PCB will be easily checked by AOI, or X-ray inspection will be used in the case of BGA components. If there’s any fault, it is traced easily. Moreover, repairing a single-layer PCB is simpler and simpler.

Disadvantages of Single Layer PCB

Although single-sided printed circuit boards are widely used, it isn’t easy to meet more and more complex applications due to their overly simple wiring and design. Everything is like a coin with two sides; a single-sided PCB has significant advantages and disadvantages that cannot be bypassed.

Large Size (Extra Dimensions)

In the case of multilayer PCBs, the circuit is distributed all told layers. Therefore, the circuit doesn't take much space on the board. Moreover, the circuit looks clean. On the opposite hand, the circuit of the single-layer PCB is present in one layer only. Thus, the circuit takes more room on the board; the board is going to be larger.

Cannot Deal with Complex Designs

If the necessity of your project could be a complex circuit, you cannot implement it on single-layer PCBs. There are some limitations, so not everything is achieved by a single-layer PCB.

Slow Speed

Single-layer PCBs offer slow speed and transmission as compared to multilayer PCBs. If you wish for high-speed, you would like to travel for a double-layer or multilayer PCB.

Cost of Single Layer PCB

The Single Sided PCB Price depends on various factors. a number of the factors are primary, while some are secondary. The primary thing is the style of the base material. You’ll be able to choose metal, FR-4, PTFE, or other materials. Together with the kind of fabric, the thickness of the bottom also matters. Then, it’s important to live the scale of the boarding gate. These two are the foremost important factors in PCB production. After that, you’ll be able to consider the surface finish, copper thickness, via filling, tracing, holes, and a few other factors. Buyers also require PCB assembly services. During this case, you wish to feature the value of the components and testing. The price of the PCB also depends on the order. High volume orders will provide you with less cost per piece. So, you’ll be able to also reduce the value if you have got a bulk order.

Applications of Single Layer PCB

As we all know the only layer PCBs are very simple, but these are still utilized in most complex devices. There are dozens of applications where a single-layer PCB is used. As long as the desired results are often achieved by the only conductive layer, it’s recommended and cost-effective to pick out a single-layer PCB rather than a multilayer PCB. The majority of simple devices that we use contain a single-layer board. For complex applications and circuits, it’s necessary to own more layers within the PCB. A number of which are listed below.

- These are used in digital camera circuits.

- These are utilized in radio and stereo equipment circuits.

- These are utilized in photocopy and printer machines circuits.

- These are utilized in digital calculators which only contain one PCB.

- These are used in slot machine circuits.

- These are used in switching relays which are mostly used in the automotive and power industry.

- These are used in solid-state drives which are mostly utilized in the power industry.

- These are utilized in coffee-making machine circuits.

- These are used in digital microwave timer circuits to modify on or off the oven timely.

- These are used in LED lighting circuits for creating an influence lighting circuit.

- These are utilized in packing machines which are mostly utilized in the packing industry.

- These are used in timing circuits to start or off the machine timely.

- These are used in sensor product circuits.

- These are used in surveillance machine circuits.

- These are used in digital and analog power supply circuits.

Single-Sided PCB Manufacturing Process

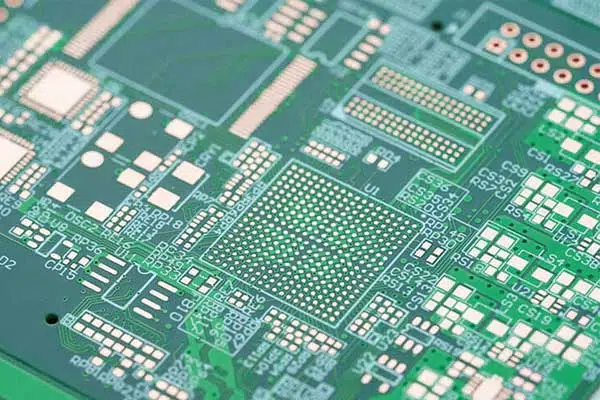

Single Layer PCB Stack Up

The stack up in a single-layer PCB is kind of simple. There are only two primary layers, but if we count the whole number of layers, including the solder mask, surface finish, and silkscreen, then there’ll be more layers in total. However, the important layers are only two layers: The conductive Layer and Base Layer.

Conductive Layer

The conductive layer conducts the signals and transmits the electrons. there’s just one conductive layer in single-layer PCBs, and it’s usually made from copper. Other materials, like Gold and Silver, may also be used as a conductive layer, but Copper is the most cost-effective and feasible.

Base Layer

The base layer of PCBs can vary. The commonly used base layer is FR-4; however, metals are used as a base material. The bottom layers provide a platform or base to all or any other layers. This is often the inspiration layer on which copper layer, silkscreen, and other layers are applied. PCBs can further be classified on the idea of the bottom layer.

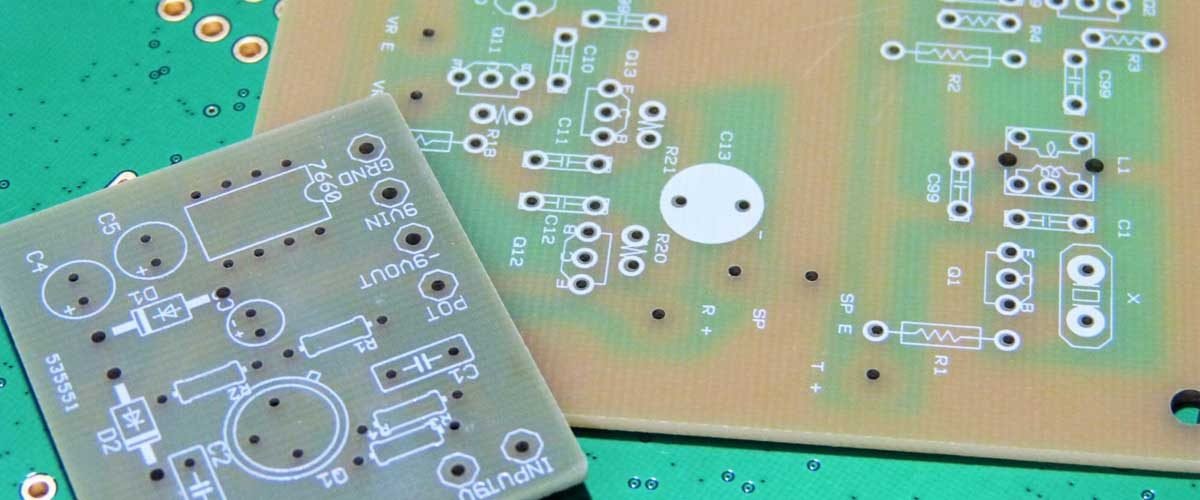

Single Side PCB Material

Printed single-sided PCB is usually manufactured from foil-clad and copper-clad laminates. The plate selection should consider electrical performance, feasibility, processing requirements, economic indicators, etc. Commonly used copper-clad laminates include copper-clad phenol paper laminates, copper-clad epoxy paper laminates, and copper-clad laminates. For multilayer PCB, foil epoxy glass cloth laminate, copper-clad epoxy phenol glass cloth laminate, copper-clad PTFE glass cloth laminate, and epoxy glass cloth are used.

Buy Single Layer PCBs from JHYPCB

JHYPCB is one in all the leading PCB and PCBA service providers in China. we’ve got an oversized facility where we are able to handle small to large volume orders. We will provide any single-layer PCB, including metal core PCB, high-frequency PCB, flexible PCB, HDI PCB, impedance control PCB, and heavy copper PCB. There’s no limitation on order; you’ll be able to order one PCB also. We provide quick prototype and assembly services under a strictly controlled management system. We are ISO, UL, or RoHS certified in order that you’ll order confidently.

FAQs

Printed circuit boards are divided into single-sided circuit boards, double-sided circuit boards, and multi-layer circuit boards. The most fundamental difference between them is the difference in the number of layers:

- A single-sided circuit board has only one copper layer;

- Double-sided circuit boards have two copper layers;

- Multilayer circuit boards are printed circuit boards with three or more copper layers.

Single layer PCB, or single sided PCB, or one layer PCB, refers to a printed circuit board with only one copper layer. It is widely used because of its simple design, low manufacturing difficulty and low cost.

Printed circuit boards have many working layers, such as Signal Layer (copper layer), Silkscreen layer, Internal Planes, Top layer, Bottom layer, Solder mask layer, etc.

PCB is divided into rigid PCB and flexible PCB. Rigid PCB substrate is usually glass fiber, namely FR-4. "FR-4" imparts hardness and thickness to the printed wiring board. In addition to FR4, iron, aluminum, ceramics, etc., are all used to manufacture printed circuit boards. Flexible circuit boards are usually processed from high-temperature resistant plastics, namely polyimide.

The printed circuit board is an essential electronic part, a support body for electronic components, and a carrier for the electrical connection of electronic components. The printed circuit board reduces the wiring footprint and organizes the wires in a clear layout.