PCB Manufacturing Services

Rogers PCB Fabrication Service

What is Rogers PCB?

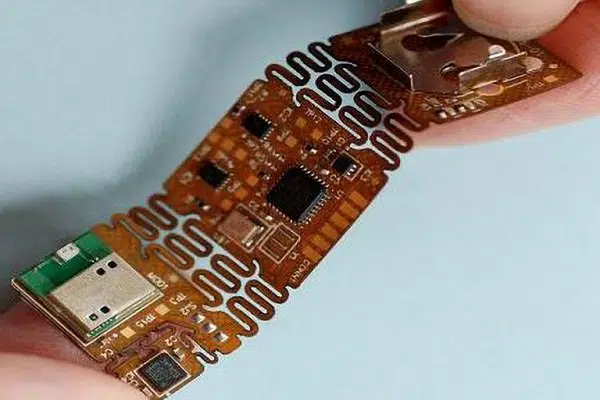

Rogers PCB is a form of a high-frequency board that staple is produced by Rogers company. It’s different from the traditional PCB board—epoxy resin (FR4). It’s no fiber within the middle and uses a ceramic base because of the high-frequency material. Rogers printed circuit board has more dielectric persistent and temperature constancy. Its dielectric constant thermal expansion coefficient is incredibly according to copper foil, which may be wont to improve the deficiencies of PTFE substrates. it’s very suitable for high-speed electronic design, commercial microwave, and oftenest applications. Its tide absorption is right for high-humidity applications, providing customers within the high-frequency board industry with the best quality materials and related resources, which fundamentally enhance product quality.

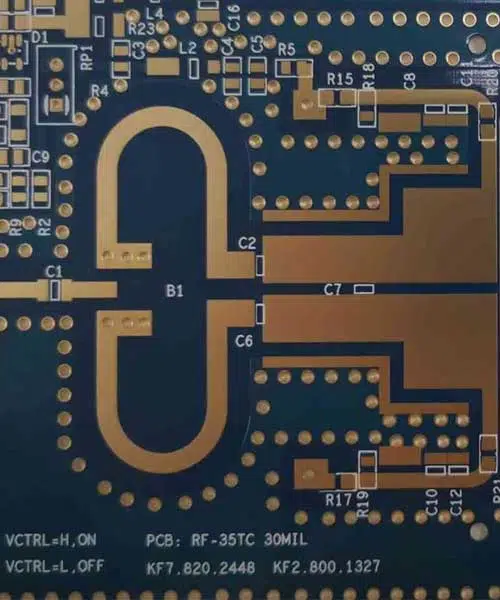

ROGERS 4003C and ROGERS 4350B have brilliant small dielectric loss features. As a result, they supply a more cost-effective and processable high-frequency material selection than PTFE. They’re widely utilized in antennas of the cellular base station and power amplifiers, microwave point-to-point connection (P2P), automotive radars and sensors, frequency identification (RFID), direct broadcast satellite high-frequency head (LNB), and other fields. Additionally, the X and Y-axis’s thermal expansion coefficient is analogous to copper’s. The expansion coefficient of the Z-axis is way below FR4 (46ppm/oC) and contains a higher Tg value (>280oC), thus ensuring good thermal stability. The dimensional stability and high reliability of the whole product in PCB processing and assembly will bring more benefits to the look of multilayer circuits.

When the circuit’s operating frequency is above 500MHz, the range of materials that style engineers can choose is significantly reduced. Rogers RO4350B material allows RF engineers to conveniently design circuits, like network matching and impedance control of transmission lines. Because of its low dielectric loss characteristics, RO4350B material has more advantages in high-frequency applications than ordinary circuit raw materials. Its dielectric constant with temperature fluctuation is nearly very cheap among similar materials. In an exceedingly wide frequency range, its dielectric constant is additionally relatively stable at 3.48; the recommended design value is 3.66. Lora copper foil can reduce the insertion loss, which makes the fabric suitable for broadband applications.

Why choose Rogers PCB?

Benefits of the Rogers PCB

Printed circuit boards developed from the Rogers material have multiple benefits, and these include the subsequent.

- Rogers PCB possesses low moisture absorption and thermal expansion, besides solid dimensional stability under diverse conditions.

- Rogers PCB material possesses high compatibility and ease in terms of fabrication due to its thinness (normally 0.1mm)

- It also has exceptional thermal management, making it ideal for circuits and electronic elements or devices producing excess heat.

- Another crucial feature that proves so useful entails reduced outgassing, especially in space applications.

- The Rogers printed circuit board matches the trace dimensions and locations, consequently improving the impedance control.

- Rogers printed circuit board offers a stable high-frequency performance.

Applications of Rogers PCB

The Rogers PCBs have numerous applications spanning diverse sectors. It includes the subsequent.

- You can use the Rogers PCB as crucial parts of antennas for the cellular base station, direct broadcast satellite, communication systems, microwave equipment, 5G modern stations, carrier-grade enabled Wi-Fi, etc.

- Automotive industry. The Rogers printed circuit boards can get deployed in automated/mechanized equipment (ATE), automotive radar, sensors, etc.

- RF Engineering. you’ll also deploy the Rogers printed circuit boards in power amplifiers, IP infrastructure, RF Identification tags, etc.

- Aeronautic engineering. The Rogers PCB also can get deployed in ACAS or aircraft collision avoidance systems, backhaul radios, microstrip antennas, etc.

- Rogers PCBs also get utilized in DAS and ADAS (advanced driver assistance systems), among other useful computer areas.

- In the military, the Rogers PCB gets utilized in radio communication systems, jamming systems, etc.

Factors to Consider When Choosing a Rogers Material

Although experienced Rogers PCB manufacturers will guide you on the most effective Rogers substrates, still knowing your application requirement is extremely important. except for this, here are some more factors supported which you decide on the proper Rogers material:

- Coefficient of thermal expansion

Going by the principle of things expanding when heated, PCB materials also expand when exposed to a particular temperature. Typically, they expand when the temperature exceeds the set glass transition temperature. the speed at which they expand beyond this temperature is termed the coefficient of thermal expansion and is measured in parts per million (ppm).

- Dielectric constant

A stable dielectric constant is crucial, especially in applications with high operating frequencies. The dielectric constant is largely the number of charges stored in an exceedingly PCB material, the high value of which ends in higher capacitance and increased voltage through the PCB. Rogers 4350B incorporates a dielectric constant of 3.66 and is hence ideal for microwave point-to-point links.

- Moisture absorption

Ideally, the fabric mustn’t absorb any moisture even when dipped in water; however, this is often highly unrealistic. But it’s important the moisture absorption rate is minimal. Most materials used for PCBs have a moisture absorption rate of anything between 0.01% and 0.2%. Materials with low absorption rates will have better thermal and electrical properties.

- Decomposition temperature

The most and minimum temperature a PCB can withstand should be decided supported by the application, and designed accordingly using the proper materials. There should be a reversal mechanism in situ if by any chance the temperature exceeds its upper limit. Otherwise, the PCB would decompose and lose some percentage of its mass. The best upper limit temperature for many applications would be 350 degrees Celsius. The decomposition temperature should be set at anything beyond this.

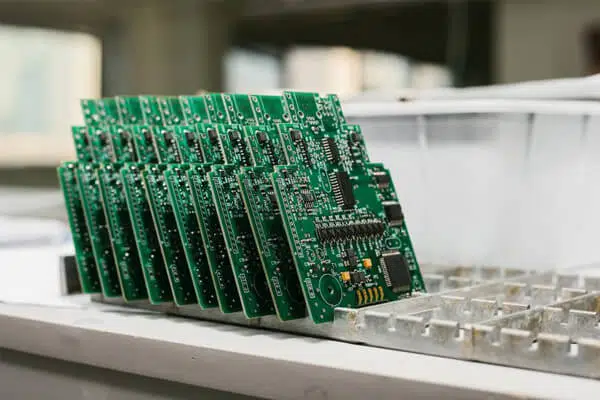

Are you looking to use Roger’s materials in your PCBs and want a trusted Rogers PCB manufacturer to assist you with it? If yes, confirm you approach a reliable player with much experience designing and assembling complex PCBs. JHYPCB is a well-known Rogers PCB manufacturer, supplier, and assembler with over many years of experience. The corporate makes various sorts of PCBs using Roger’s materials.

Rogers PCB Material

The Diverse Rogers PCB Material Types

If you would like to style and obtain your printed circuit board produced, it helps to contemplate the three kinds of Rogers PCB materials. The materials can get categorized into three categories, and this includes the subsequent.

- Metal claddings. the primary of the three categories. It can come as electrodeposited, rolled, resistive foil, and electrodeposited reverse pickled/treated metal cladding.

- Bonding material. The second category comes as woven glass, hydrocarbon, ceramic PTFE bond ply, prepreg, and TECA (Thermoset Thermal & Electrically Conductive Adhesive) film.

- Different laminates. It comes because the last of the categories and features PTFE ceramic, hydrocarbon, random PTFE fiber, glass-reinforced & cross-plied woven PTFE, and modified epoxy laminates with woven-glass reinforcement.

Related PCB Fabrication Services

Related PCB Assembly Services

Related Reading

- What is the PCB Fabrication Process?

- How much does PCB Fabrication Cost?

- PCB Fabrication and Assembly Services Manufacturer In China

- What are the Advantages of a Prototype PCB Assembly?

- Why Choose China PCB Assembly Manufacturer?

- What is PCB Panelization and its Methods in PCB Manufacturing?

- What are the Benefits of Turnkey PCB Assembly?

JHYPCB can provide you with custom Rogers PCB manufacturing services. We have Rogers PCB material in stock in our warehouse. You can use our online Rogers Manufacturing Quote Request Form to get your desired quote. You can also send the Gerber file to sales@pcbjhy.com by email for Rogers PCB fabrication; if you need PCB assembly service, please send the BOM and Gerber file to sales@pcbjhy.com; our professional service staff will reply to you as soon as possible.