Selecting the right materials is crucial to the success of any PCB assembly project. The materials used in PCB manufacturing not only determine the functionality and performance of the end product but also significantly impact the assembled boards’ quality, reliability, and lifespan. When sourcing components and materials for your PCB assembly, making informed choices is critical, considering factors such as operating conditions, production volume, compliance standards, and cost. The wrong material selection can lead to premature product failures, damaging your reputation. On the other hand, the right choice of materials ensures your PCB assemblies live up to design expectations and operate smoothly for years. This article guides choosing the most suitable materials for your application based on today’s popular options for PCB substrate, solder, adhesives, coatings, and components. Careful evaluation of material properties will enable you to balance performance requirements with practical constraints.

Untold Facts About PCB Assembly Materials

Undoubtedly, the quality of your circuit boards depends on the materials used in their manufacturing and assembly. It doesn’t just determine whether such a board is going to perform optimally. Also, it can influence the applications for which such a board will be suitable. Without the right materials, it will be very difficult to get high-quality PCB assembly services.

Do you want to know the best part about all of these? It is a fact that JingHongYi PCB (HK) Co., Limited exists to ensure you have access to PCBs that have been manufactured with nothing but the best materials. Apart from being able to work with different reputable companies in the field of manufacturing different applications, we have always practiced using premium materials.

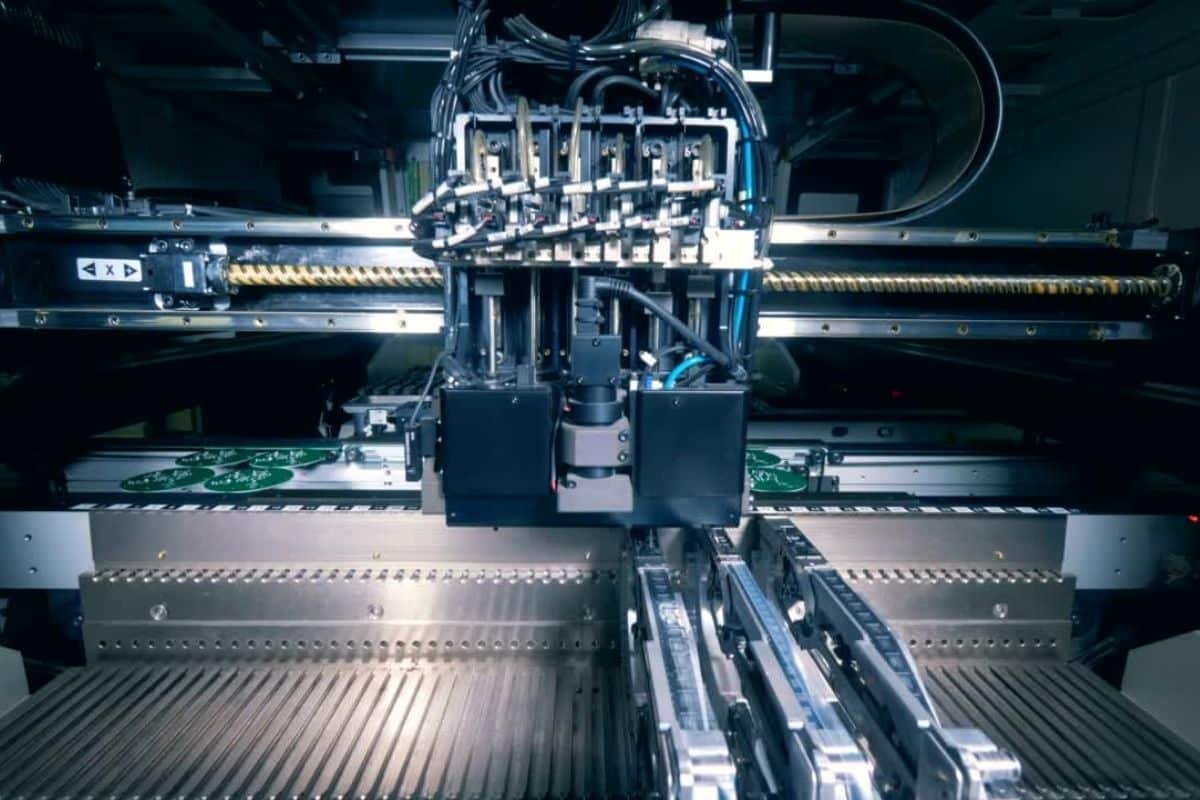

When it comes to PCB assembly, several factors must be considered to ensure you are getting the perfect finished product. At JHYPCB, we always look at the features which available materials possess. This helps our experts in deciding on whether they will be perfect for your project or not. Some of what we consider are:

- Mechanical properties

- Chemical properties

- Electrical properties

- Thermal properties

- And more

This is part of our approach to choosing the right materials for your PCB assembly and manufacturing. Our primary goal entails ensuring that selected materials are compatible with your preferred application and design. Is your PCB project looking technical and complicated? Do you feel such will be difficult to execute? There is no need to worry because we have a very vast understanding of PCB materials. We have handled different kinds of PCB assembly projects in the past involving complex and simple materials.

The best part is that we always aim to deliver beyond your expectations. We believe that with the perfect selection of materials, you can access performance-driven PCBs.

Overview of Common PCB Assembly Materials

There are a variety of materials used in the assembly of printed circuit boards that serve different purposes. The PCB substrate forms the foundation of the assembly. Common rigid PCB substrates include materials like FR-4, ceramics, and composites. Additional materials bond components to the PCB board and form conductive pathways between them. These include soldering metals, conductive adhesives, and solders. Protective coatings are often applied to the assembled PCB to shield components and connections from environmental factors. Common options include acrylic, urethane, and silicone conformal coatings. Other materials like plating, stiffeners, spacers, and heatsinks may also be used depending on the specific application. When selecting PCB assembly materials, factors like operating temperature range, circuit density, frequency, environmental exposure, production volume, and compliance standards must be evaluated to find optimal performance, quality, and cost balance.

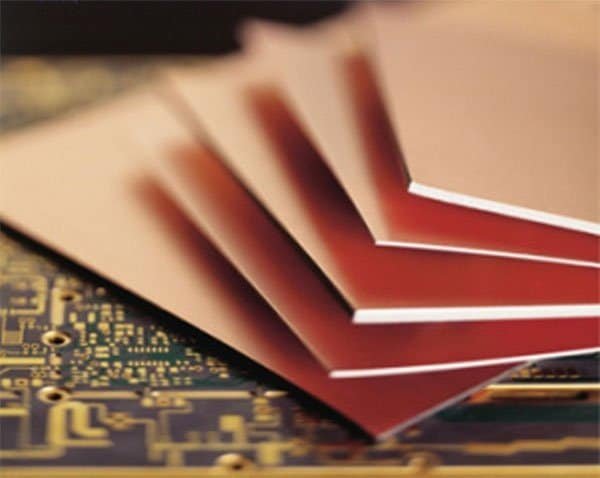

Choosing the Right PCB Substrate Material

The substrate material forms the foundation of the PCB assembly and is a critical component. Today’s most common rigid PCB substrate material is FR-4, a glass-reinforced epoxy laminate. FR-4 offers a good balance of electrical performance, mechanical stability, and cost-effectiveness. It works well for many general-purpose applications. Higher-performance substrate materials such as ceramics or composites can be used for more demanding high-frequency or high-temperature applications. Ceramic-based PCBs provide excellent thermal conductivity and dimensional stability at high temperatures. But they are relatively more expensive than FR-4. Metal core PCBs and ceramic-filled composites offer a lower-cost alternative with moderate thermal performance. The substrate thickness, copper weight, dielectric constant, and loss tangent are other important parameters to evaluate. In summary, factors like operating frequency, power levels, thermal loads, and budget play a role in selecting the optimal PCB substrate material.

Solder Options for PCB Assembly

Solder is used to form both electrical and mechanical connections between components and PCBs during assembly. For many years, tin-lead solder was the primary choice, but environmental concerns have led to the adoption of lead-free solders today. Common lead-free solder alloys include tin-silver-copper (SAC), tin-copper (SnCu), and tin-silver (SnAg). Lead-free solder has a higher melting point, which can introduce challenges during processing. The composition must be selected carefully to ensure reliable joint integrity and prevent tin whisker growth issues. SAC alloys offer good wetting and flow characteristics, while SnCu is typically chosen when higher thermal cycling reliability is needed. Cost, availability, and specific assembly requirements also impact solder selection. Additional solder materials like conductive and silver-filled epoxies can be an alternative to traditional tin-based solders for attachments needing high electrical and thermal conductivity with high strength. The right solder materials that match the PCB assembly requirements must be sourced from reputable suppliers to ensure consistent, high-quality results.

Choosing the Right Adhesive for PCB Assemblies

Adhesives play a critical role in PCB assemblies, providing mechanical attachment and, in some cases, electrical connections between components and circuit boards. When selecting an adhesive, key factors include conductivity requirements, bond strength needs, operating temperature range, and flexibility.

Conductive epoxies filled with silver or other metal particles are the best choice for applications requiring electrical conductivity between bonded parts. Dielectric epoxies and other non-conductive adhesives for purely mechanical attachments provide firm bonding without shorting electrical connections.

Adhesives like epoxies or silicones can be selected over various viscosities and curing methods to suit the assembly needs. The right adhesive balance of bond strength, temperature resistance, and flexibility helps ensure durable, long-lasting bonds between delicate components and PCBs despite thermal cycling or shocks.

Matching the adhesive properties precisely to the assembly materials and operating conditions is key to maximizing the reliability and lifespan of PCB assemblies.

Protecting PCB Assemblies with Conformal Coatings

Conformal coatings are polymer materials applied in thin layers over the entire PCB assembly to protect from environmental factors such as moisture, dust, chemicals, and temperature extremes. Common coating options include acrylic, silicone, urethane, parylene, and epoxy-based materials.

Acrylic coatings are economical and easy to apply, providing decent moisture and chemical resistance. Silicone coats offer enhanced thermal stability and flexibility but weaker moisture barrier properties. Urethanes like polyurethane provide tough, abrasion-resistant coatings. Parylene forms a uniform pinhole-free conformal coating with excellent dielectric strength. Selecting the right coating involves evaluating resin chemistry, application method, thermal rating, flexibility, and dielectric properties to match the specific assembly and operating needs.

Conformal coatings are an important process in PCB assembly to help components function reliably for their full lifespan despite challenging operating environments. The coating material should be tested for compatibility and application effectiveness during the prototype phase to ensure optimal protection.

Supplementary Components for PCB Assembly

In addition to the core PCB substrate, solder, adhesives, and coatings, PCB assemblies may utilize supplementary components and hardware to complete the build.

Card-edge or circular connectors allow detachable integration of the assembled PCB with cables or other system components. Spacers and standoffs provide fixed separation between PCBs or other assembly layers. Screws and fasteners securely hold components together.

Some assemblies may also require specialized components like heatsinks, shields, or stiffeners for thermal management, EMI reduction, or mechanical support. Multilayer PCBs often incorporate vias and conductive through holes for interlayer connections.

Choosing reliable, precision-made supplementary components ensures robust mechanical integration and connectivity for the full PCB assembly. Component selection should consider factors like assembly sequences, servicing needs, vibration resistance, and thermal management.

Hire Our Wholesale PCB Assembly And Manufacturing

Do you want us to handle the entire process of material procurement? It doesn’t matter as we are capable of helping out in such regards. Our experts will get the best materials available in the market. These have uncompromising quality and will ensure the optimum performance of your circuit board.

Given our wholesale PCB assembly and manufacturing services, there is no doubting the fact that you will always get nothing but the best. For more details, try to contact us today.