Printed circuit boards have become essential components in virtually all electronic devices and equipment today. From computers and smartphones to medical devices and cars, PCBs provide the foundation for any electronic system. For companies developing new electronic hardware, having access to fast, high-quality PCB assembly is critical.

However, managing the PCB assembly process in-house requires significant capital investment in equipment and expertise in specialized skills like soldering and quality control. This is where outsourcing PCB assembly to a turnkey service provider offers important advantages.

Turnkey PCB assembly refers to outsourcing the entire assembly process, including sourcing components, soldering, testing, inspection, and more to an external supplier. With turnkey assembly, engineers can simply provide the PCB fabrication files and component list, and the turnkey assembler will handle the rest.

This blog will dive into the top benefits of using turnkey PCB assembly rather than managing the process internally. We’ll explore how turnkey assembly enables faster time-to-market, higher quality, flexibility, and cost-effectiveness. Understanding these advantages is key for any company looking to optimize their PCB manufacturing workflows.

What is Turnkey PCB Assembly?

Most electronics startups find the traditional ways of sourcing PCBs cumbersome thanks to costly, slow, and error-prone processes. Fortunately, turnkey PCB assembly is now available to businesses that wish to receive circuit boards for products within the shortest interval. If you wish for a competitive edge in the market, you would like PCBs to be used to develop, test, and introduce new products before your competitors. And that’s where turnkey PCB assembly makes a difference.

PCB manufacturing requires a posh procedure to ensure the finished product delivers a seamless performance. You’ll outsource your PCB manufacturing to a turnkey PCB manufacturer. A turnkey manufacturer will provide a one-stop solution for reliable printed circuit board production. You are doing little to cope with multiple vendors for PCB production and assembly. A turnkey PCB assembly will handle each production stage, from the procurement of components to the style of the boards.

Turnkey PCB Assembly offers a whole electronics setup with the essential solutions to get each completed item. Necessarily, our company JHYPCB is relied on. When an order is placed by any customer, our supplier takes care of all instruments, different from prototyping to incomplete buying assembly, and also product packaging. A turnkey PCB manufacturing solution can facilitate your boards’ planning, fabrication, and assembly, including testing, packaging, and shipping the ultimate product. The manufacturer agrees to totally design, construct, and equip the assembly facility and switch the project over to the purchaser after it’s able to be used immediately.

Reduced Time to Market

One of the most impactful benefits of turnkey PCB assembly is significantly faster time-to-market for new electronics products. The specialized skills and streamlined workflows of turnkey assemblers can shave weeks or months off manufacturing schedules.

For any new product involving custom PCBs, thorough prototyping and testing is critical before release. However, repetitive in-house assembly and debugging of PCB prototypes drag down development timelines. Outsourcing prototype builds, and modifications to an experienced turnkey assembler accelerates iterations.

Once the design is finalized, turnkey assembly’s fast setup and turnaround times smooth the path to production. Demand can be highly dynamic, requiring the ability to scale production up and down quickly. Turnkey assembly provides flexible capacity that is impractical to match internally.

Turnkey providers also readily take on challenges like advanced PCBs, odd-form factor designs, and high mix/low volume production – all scenarios that typically hamper speed for in-house assembly. Their specialized expertise makes the routine difficult.

For instance, dense, fragile boards prone to warping, like multi-layer ceramic PCBs, can be tedious. But turnkey assemblers have honed the process know-how and precision equipment to handle such complex assemblies and still deliver quickly and expertly.

The ability to easily ramp up and down production enables agile responses to changing market demand. Turnkey assembly gives product teams speed, quality, and versatility – allowing them to seize opportunities and gain competitive advantage with accelerated time-to-market.

Access to Advanced Technology and Equipment

One of the major advantages of outsourcing PCB assembly to a turnkey provider is gaining access to cutting-edge technologies and equipment that would involve substantial investments if done in-house.

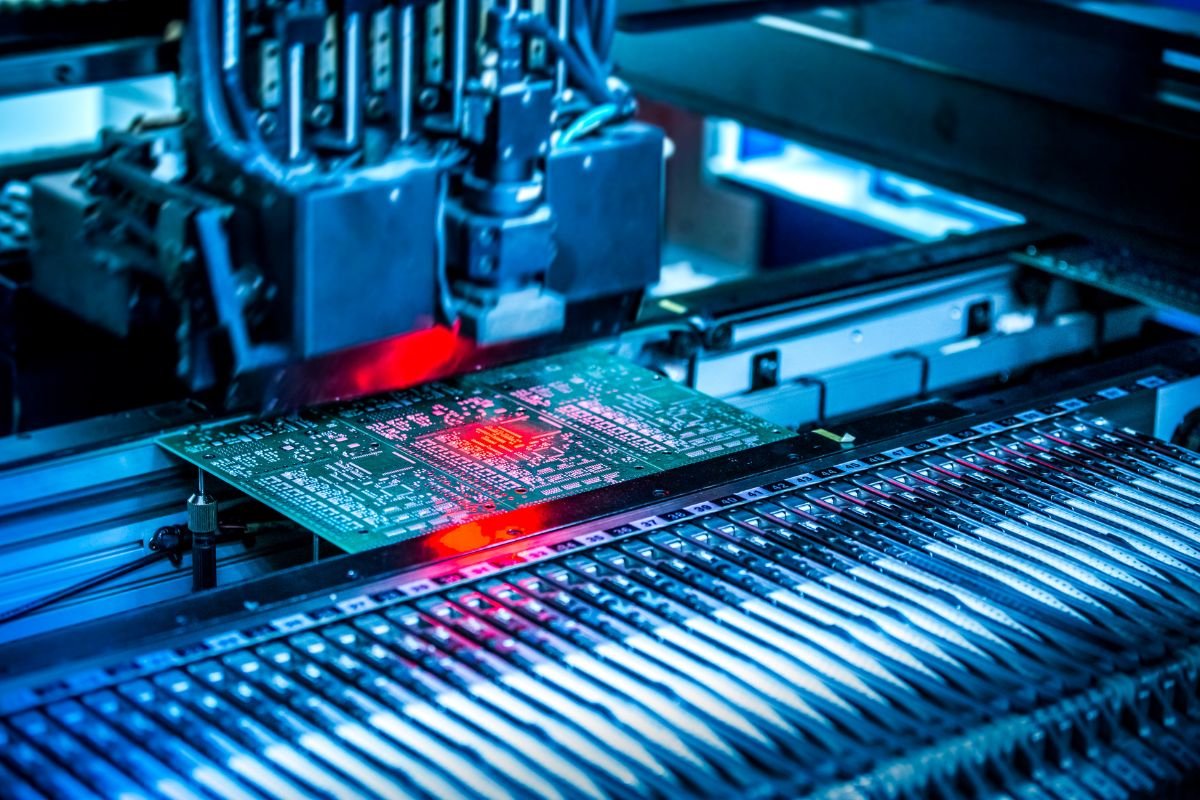

Top turnkey assemblers continuously upgrade their capabilities with the latest advancements in assembly machinery. They leverage high-precision pick-and-place machines, advanced soldering systems like selective wave soldering, sophisticated inspection equipment, and more. Keeping pace with such capital investments in-house is challenging.

Turnkey assemblers also employ state-of-the-art manufacturing software and processes. Their engineers are highly trained to handle the latest PCB technologies like multi-layer boards, HDI PCBs, flexible circuits, and rigorous quality standards.

For instance, turnkey assembly makes it feasible to incorporate advanced PCBs like multilayer flex-rigid boards in products. In-house, the expertise and equipment needed to assemble flex-rigid PCBs reliably are difficult to acquire. Outsourcing to an experienced turnkey assembler solves this bottleneck.

The scale of leading turnkey PCB assembly providers also creates economies of scale. Their high production volumes justify investments in the most advanced equipment. This level of capital expenditure is not sustainable for most companies’ internal assembly operations.

By leveraging turnkey assembly, product teams can stay on the cutting edge of PCB technologies and be assured of high-quality outputs without excessive capital costs. The specialized expertise and precision machinery of turnkey assemblers enable innovation and shorter time-to-market for advanced electronics.

Improved Quality and Reliability

Stringent quality control and reliable processes are crucial for electronics assembly, as defects can lead to complete product failures. Turnkey PCB assemblers have the specialized expertise and discipline needed to meet the highest quality and reliability standards.

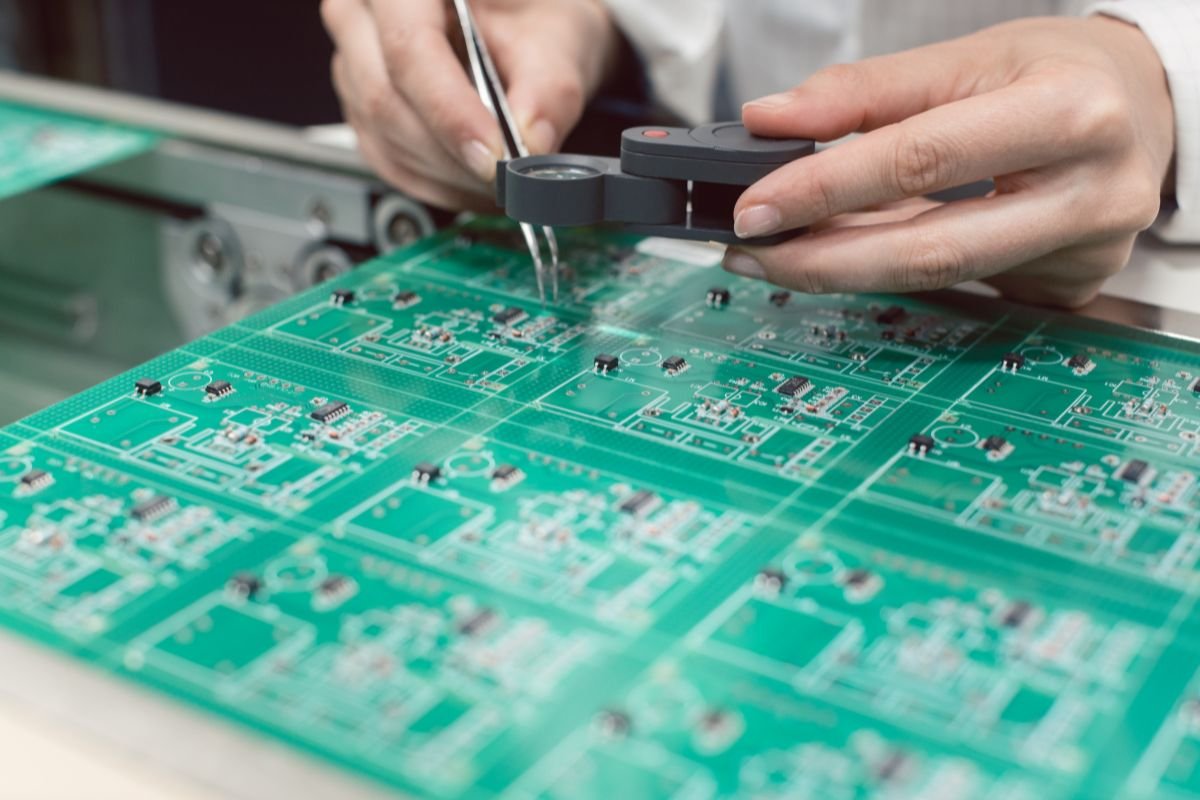

The staff at turnkey assembly facilities are trained to follow meticulous protocols for every production step. From component inspection to soldering, testing, and packaging, standardized workflows are designed to eliminate errors and minimize variability.

Sophisticated inspection equipment like x-ray imaging and automated optical inspection is used to catch assembly issues before products ship. Any defects can be quickly identified and corrected. Turnkey providers undertake extensive quality audits and analysis to improve processes continuously.

For sensitive electronics like medical devices or automotive systems, the reliability and workmanship of PCB assembly has serious implications for field failure rates. Turnkey assemblers are routinely certified to the highest industry standards, like ISO 9001, ISO 13485, IATF 16949, and AS9100.

These assemblers have often cultivated relationships with leading component suppliers and adopted robust component qualification procedures. This ensures that only pre-validated, authentic parts make it into production using vetted custom-testing fixtures.

With turnkey assembly, R&D engineers can be confident that the realities of manufacturing scale will not compromise quality. The combination of turnkey expertise, systematic quality processes, certified materials, and extensive testing delivers unparalleled reliability.

Flexibility and Scalability

The dynamic nature of product development and fluctuating market demand makes production flexibility critical. Turnkey PCB assembly enables the rapid scalability and adaptability needed to meet changing requirements.

Companies must make large investments in fixed assets like machinery and inventory with in-house assembly. Sudden spikes or plunges in orders are hard to manage. Turnkey assembly instead provides flexible capacity that can rapidly scale up or down.

Turnkey providers maintain a broad inventory of components and production readiness for high-mix, variable batch sizes. The extensive supplier networks and quick design-for-manufacturing feedback from turnkey assemblers facilitate adapting to part shortages or design changes.

For startups and smaller companies, turnkey assembly avoids over-investing in assembly infrastructure too early. As product sales and demand mature, production can seamlessly be shifted from turnkey to in-house if desired, after volumes justify the assets.

Outsourcing provides insurance against unforeseen events. Geopolitical factors, natural disasters, supply chain shocks – any sudden external disruption that would torpedo internal assembly can be absorbed by the turnkey’s flexible capacity.

Engineers at turnkey assemblers can also readily incorporate component or design revisions—no need to discard existing inventory or equipment. Turnkey assembly integration provides the agility to handle ongoing product evolution smoothly.

The scalability of turnkey minimizes risks from demand fluctuations or product changes. Companies can execute faster with lean, adaptable assembly infrastructure.

Cost Savings

In addition to accelerated time-to-market, higher quality, and increased flexibility, turnkey PCB assembly also delivers significant cost savings compared to in-house assembly.

Turnkey assemblers operate at a large scale and service many customers. This allows them to reap benefits like bulk component pricing and optimized utilization of equipment and labor. Those savings can be passed along through lower assembly fees.

Building similar assembly capacity in-house would require substantial investment in facilities, equipment, hiring specialized operators and engineers, and inventory. Turnkey assembly avoids these major fixed costs.

For low to medium production volumes, turnkey assembly is clearly more cost-effective. But even at higher volumes, turnkey can lower total unit costs by leveraging economies of scale and specialization.

Turnkey assembly also reduces costs in areas like logistics. Mass purchasing power enables turnkey assemblers to secure discounted freight rates. Consolidating many customers’ orders also improves logistics efficiency.

Since turnkey focuses solely on assembly, they hone the expertise and workflow optimization to maximize throughput and minimize overheads. Internal assembly operations often struggle with poor utilization rates and excessive overhead expenses.

While exact cost saving varies case-by-case, studies show turnkey assembly reduces total unit costs by 25% to over 50%. And those savings will only compound as production scales. By leveraging turnkey assembly, manufacturing costs need not hamper product innovation.

Conclusion

The benefits of outsourcing PCB assembly to a turnkey provider are multi-fold. Companies can reduce time-to-market by leveraging specialized skills and streamlined processes. Access to cutting-edge equipment and expertise in the latest PCB technologies enables innovation.

Turnkey assembly ensures reliability and quality by following rigorous protocols. Flexible capacity allows rapid scalability to meet demand fluctuations. And lower costs can be realized thanks to economies of scale.

For any company looking to optimize its electronics manufacturing operations, turnkey PCB assembly warrants serious consideration. The headaches of managing in-house assembly infrastructure are eliminated. Engineers are freed to focus their efforts on design and development.

Of course, the suitability of turnkey versus in-house assembly depends on individual product needs and production volumes. But turnkey PCB assembly services deliver advantages across the spectrum, from prototypes to high-volume production.

By partnering with a qualified turnkey provider, companies can execute their vision faster and cost-efficiently. The result is higher performance reliable products that delight customers. Turnkey assembly promises technical capabilities beyond feasible in-house, avoiding operational burdens.