Overview

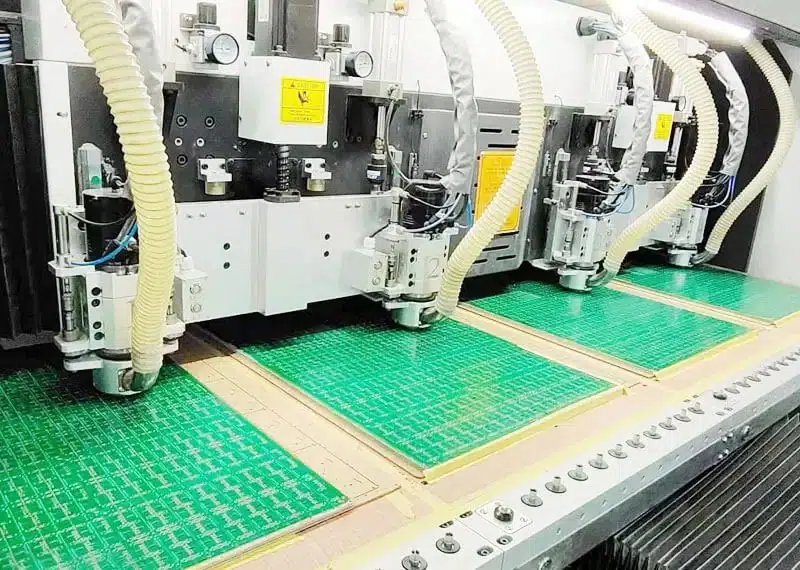

PCBs are the backbone of electronics and a faulty PCB means a waste of cash and time. What’s worse is finding the identical fault in multiple PCBs you’ve just manufactured. This is often exactly why it’s best to check your PCB design to create sure there aren’t any faults and it’s functioning properly. After all, small mistakes can often go undetected and a few faults will be invisible to the eye. So, before you choose production, you must test your design. You’ll be able to do so by prototyping your PCB beforehand. Engineers designing printed circuit boards (PCBs) commonly generate a prototype board before full-scale manufacturing of boards for end products. Multiple prototype runs will often be included within the development of the ultimate fabricated PCB, permanently reason.

Building a printed circuit board (PCB) is over springing up with the planning and sending it off for production. Proper PCB fabrication should include a prototype stage where you send your design to form one PCB, you’ll be able to test. In this style, you’ll be able to improve your design before producing a full line. To assist you with the prototyping step, here’s everything you wish to grasp about prototype PCBs.

What is a PCB Prototype?

PCB prototypes are early samples of products built with the only real purpose of testing design ideas to determine if they work. Although most prototypes, in general, are made to check basic user functionality, engineers require somewhat, if not entirely, functional PCB prototypes to test the whole functionality of styles. Prototypes could also be developed for limited-function boards to check the proof-of-concept of single functions, before the assembly of a more complex finished product.

Build-outs of accelerating complexity can ensure quality and expected results as functions are added to the look. This can be especially useful in additional complex PCB designs where failure after final fabrication creates costly rework and redesign. Manufacturing of high-density or multi-layer boards are structures where prototyping can sharpen the techniques of PCB circuit concept-to-production. Building cost-effective prototype boards may be a specialty service offered by some PCB fabricators.

Cycling prototype boards as designs are fine-tuned and validated for functionality and reliability can speed the event of a working final design. The value of rework is significantly increased if the need or board failure is discovered later within the process. This makes prototype design software valuable for electronic engineers AND gate designers.

Why use a PCB Prototype?

Before you begin a full production run, you need to make sure that your printed circuit board (PCB) functions correctly. Since Printed Cricut Boards are an essential component of many electronic devices, if one functions poorly or fails after full production, it can cost you significantly. Prototyping your PCB earlier can help to avoid such problems and situations. A prototype PCB is all-around testing your design with the smallest investment. If you only make a design without testing it, you may lose all of your invested money from simple errors. A prototype helps you discover these flaws and adjust your designs before you conceive to full production. Employing a PCB prototyping board allows us to form necessary changes to the look beforehand without trifling and money from having to revamp the PCB afterward within the manufacturing process.

Reasons to invest in a PCB prototype

Regardless of how careful your designers are on a project, invisible problems and little mistakes always pose a threat to the ultimate product’s functionality. Usually, your engineers will use a PCB prototype early within the design process when testing the functions of PCB-based solutions. They’ll often order multiple PCB prototype runs to check one function or redesigns before moving to more complicated designs. Prototyping enables them to find any elements that need correction within the early stages of the method, which makes the project less expensive.

Types of PCB Prototypes

Engineers and designers use different types of PCB prototypes to check different design aspects. Throughout a task, your design groups may use several printed circuit boards at different phases of their design procedures. Examples of those prototypes include:

- Visual Models

They illustrate the physical aspects of printed circuit board designs and show the component structure and shape. Because of the initial prototypes in your design process, engineers use visual models to review and communicate the look easily and affordably.

- Proof-of-Concept Prototypes

These prototypes specialize in the replication of the first function of PCB boards without carrying all of the ultimate product’s capabilities. They show viability.

- Working Prototype

These are functioning boards containing all the planned functions and features of the ultimate product. They assist to identify problems and weaknesses in designs but rarely represent what or how the ultimate product will appear when finished.

- Functional Prototype

Designers make these to resemble the ultimate product. They supply the foremost accurate idea of the ultimate design.

Advantages of PCB Prototyping

PCB prototypes help speed up the method of developing a printed circuit board design through visual assistance, complete testing, and minimizing the quantity of rework required. Prototyping gets obviates guesswork by allowing engineers to quickly and accurately identify problems.

Disadvantages of PCB Prototyping

While there aren’t many cons regarding printed circuit board prototyping, it’s fully addicted to how you decide to prototype the board design. Most challenges arise when employing a breadboard. The breadboards frequently have restrictions corresponding to using software to prototype. They’re not a decent option for those functioning on a design that needs a high voltage, or one that’s very complicated. It becomes difficult to map what you’re doing, which may lead to challenges along the road.

Conclusion

Why we produce a printed circuit board Prototype? Because this is a strong tool for designers to supply time and cost-saving benefits while ensuring a top-quality final product. Its numerous benefits like reduced project timeline and costs, the flexibility to check components individually, efficient project completion, and accurate prototypes. As such, industry professionals recommend the utilization of prototyping to check new designs and revisions.

JHYPCB is a leading prototype PCB manufacturer in China, providing high-quality, quick turnaround PCB manufacturing and prototype PCB assembly services.

Related Posts

- PCB Prototype Service – PCB Prototype Manufacturer in China

- Fr4 PCB Prototype: A Brief Guide to Fr4

- PCB Prototype Europe: The Definitive Guide

- What iS The Best PCB Prototype Service?

- China PCB Prototype Service: A Brief Guide

- Canada PCB prototype: Important facts to note

- The definitive guide to a PCB prototype USA manufacturing company

- What are the Advantages of a Prototype PCB Assembly?

- Small Batch PCB Assembly Essential for Prototyping