It has been discovered that many people are confused about PCB assembly drawing. There are those who believe it is the same thing as PCB assembly. One of the reasons why you should have understood about this is that it will enable you identify the kind of services a company can render. You are in luck today having stumbled upon this article. This is because it will be aiming to explain everything about PCB assembly drawing.

The Meaning of PCB Assembly Drawing

This is simply a drawing or sketch which tends to show how and where electrical components should be positioned on a circuit board. The same way electrical appliances are drawn or sketched before getting produced, that is how circuit boards are designed. It is more like a process that precedes PCB assembly. In other words, before PCB assembly can happen successfully, there has to be PCB assembly drawing.

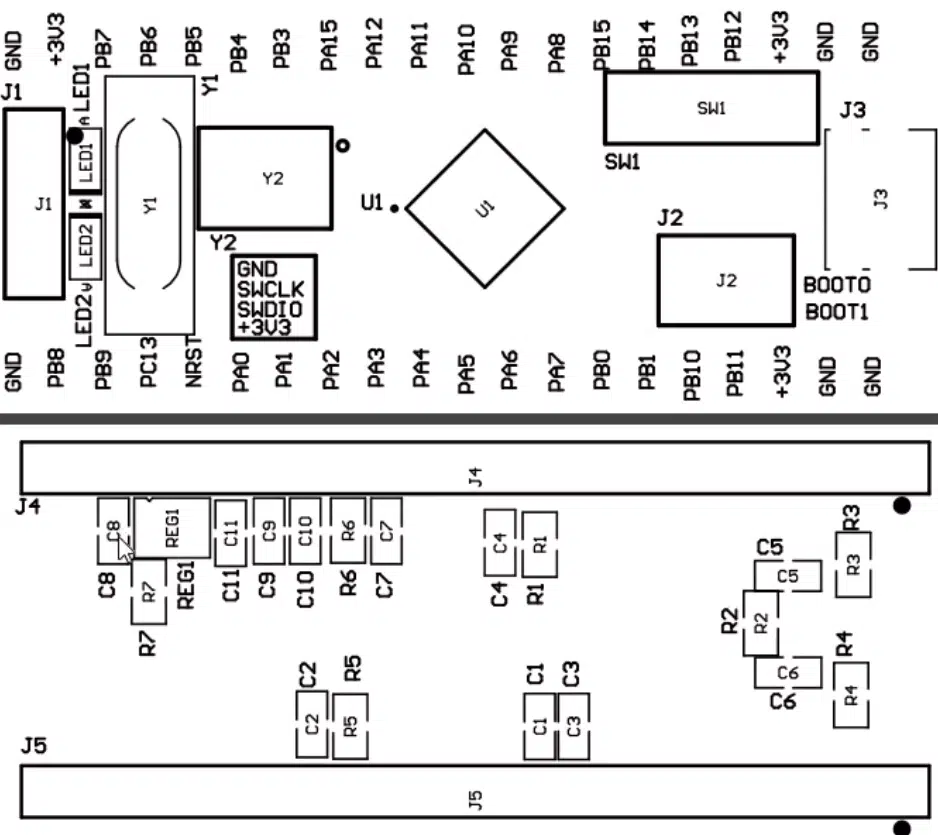

Based on the above statement, it is fair enough to say that PCB assembly drawing is a process which provides detailed information on how printed circuit boards can be assembled without hassle. It can include elements like titles, board outline, reference designators, polarity marks, surface mount & through-hole pads. It is very important that a PCB designer has vast knowledge of interpreting PCB layouts. This helps in applying the instructions as clearly stated on the PCB assembly drawing.

PCB assembly drawing usually comes in various forms. The bottom line is that they are very accurate for any manufacturer to understand and work with. Some of what a manufacturer must understand in PCB assembly drawing are parts list, cut way “expanded” views, identification label locations, mechanical parts, board outline, and drawing format. For an accurate drawing to be created, the right tools will always be required.

What Is The Purpose of An Assembly Drawing?

PCB assembly drawing has some purposes. This is why it can hardly be ignored. For instance, it has one major purpose which is to ensure that components in a circuit board are located as well as identified appropriately. In other words, it ensures accurate identification of items. Also, it can help in labeling the sequence for which an assembly process can be carried out. In other words, it can help to clearly highlight how components in a PCB should be assembled.

There are times when assembly drawing can help in stating or listing out standard requirements that will be required to ensure the process is 100% compliant with government stipulations.

What Are The Types of PCB Assembly Drawings?

There are different types of assembly drawings you should know. These are listed below:

- General Assembly Drawing – This tends to show or display the entire assembly.

- Diagrammatic Assembly Draw – In this case, the assembly is displayed or explained via the use of symbols.

- Outline Assembly Drawings – The exterior shape of the assembly is shown here.

- Exploded assembly drawing – The goal of this drawing is to reveal relationships that exist between components.

- Sub Assembly Drawings – This explains a part or component of the assembly in details.

Final Words

Given the above details, it is clear that PCB assembly drawing is a process that is crucial. In other words, it can play an essential role for successful PCB assembly.

JHYPCB is an expert in PCB assembly; we provide one-stop electronic contract manufacturing services, including turnkey PCB assembly, prototype PCB assembly, quick turn PCB assembly, low-cost PCB assembly, and low to high-volume PCB assembly services. Competitive prices and high quality will make you more competitive in the market.

Useful Resource

Altium Designer Tips #1: How to Create Assembly Drawing