Introduction

Printed circuit boards are the backbone of electronic devices and products. From smartphones and computers to appliances and vehicles, PCBs allow various electronic components, like processors, memory, controllers, resistors, capacitors, etc., to be interconnected and work together as part of a complex circuit.

The board must be fabricated and assembled before these components can be brought together on a PCB. PCB fabrication involves creating the bare circuit board from layers of conductive and insulating materials. Once the bare PCB is ready, the next step is PCB assembly. This crucial process solders all the components onto the PCB to build the final circuit board assembly.

PCB assembly transforms a bare printed circuit board into a fully functioning electronic device or product. It is an intricate process that requires expertise and the right tools and technology to ensure all the electronic components are soldered correctly onto the PCB. Improper assembly can lead to short circuits, operational failures, and reliability issues in the end product. That’s why understanding what PCB assembly entails is important for electronics manufacturers and consumers alike.

In this article, we will take a closer look at what exactly PCB assembly means, why it is a vital process, the different assembly methods used, the step-by-step assembly process, as well as the benefits of outsourcing PCB assembly to a reliable partner. Whether you’re new to PCBs or just looking to expand your knowledge, read on to demystify this critical manufacturing process.

Leading China PCB Assembly Services

As one of China’s leading PCB assembly manufacturers, our comprehensive suite of rapid and cost-effective PCB assembly services means you needn’t involve yourself in the painstaking job of components sourcing, PCB fabrication, or mounting components.

Instead, the skilled, qualified, and highly trained PCB manufacturing and assembly China team at JHYPCB can take care of any aspect of the assembly process you’d like them to – from component procurement, PCB fabrication, and mounting to soldering and inspection & testing.

We pride ourselves on getting the job done the first time on our PCB assembly express and fast PCB assembly services. Moreover, our turnaround times and your satisfaction are guaranteed.

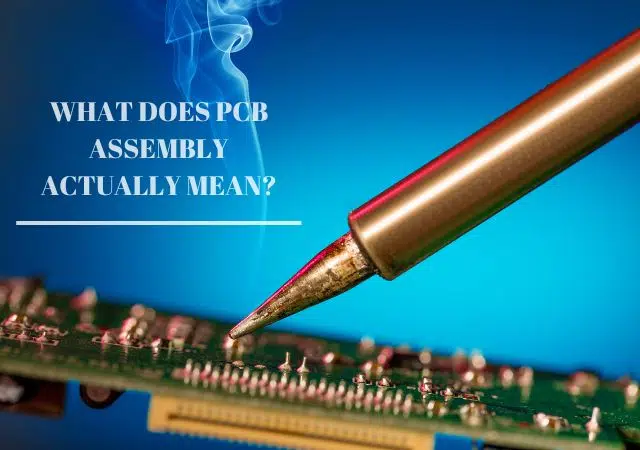

What Does PCB Assembly Actually Mean?

PCB assembly, also known as PCBA, refers to the process of soldering or assembling electronic components onto a PCB or printed circuit board. The bare PCB manufactured during fabrication provides the foundation to physically support and connect the components using conductive copper traces and pads.

Electronic components like resistors, capacitors, integrated circuits (ICs), transistors, etc., are accurately placed and soldered onto the PCB during assembly. The components are fixed in place by fusing solder alloy to copper pads on the board. The soldering connects the leads or terminals of the components to the matching pads on the PCB, both mechanically and electrically. This assembly process builds up the board and creates the circuit that gives it its desired functionality.

The end result of PCB assembly is a fully populated printed circuit board that forms the core of an electronic device or product. The assembled PCB with all electronic components soldered in place can function based on the purpose it was designed and assembled for. It provides the interconnections between components that allow them to operate in unison, communicating input and output signals to bring the electronic system to life.

In summary, PCB assembly involves placing and soldering various electrical and electronic parts, like ICs, resistors, capacitors, connectors, etc., onto a manufactured PCB using soldering techniques. It transforms the bare board into a functional electronic circuit assembly that powers end products ranging from consumer electronics to industrial equipment.

Why is PCB Assembly Important?

PCB assembly is a crucial manufacturing process that adds enormous value towards creating fully functional electronic products and devices. Here are some of the key reasons why PCB assembly is such an important process:

- It allows the creation of electronic devices – Without assembling components onto a PCB, it would not be possible to build the complex electronic circuits and systems that power endless devices we use. PCB assembly is essential to construct functioning electronics.

- It connects components properly to create functioning circuits – The purpose of a PCB is to interconnect separate electronic components and integrate them into intended circuits. Proper assembly solders each component in its right place to complete the circuit as designed.

- It ensures quality and reliability – PCB assembly must be done with immense precision and care to deliver robust, reliable electronic products. Proper techniques, the right process parameters, and thorough inspection and testing during assembly are vital.

- It adds major functionality and value – While the bare PCB forms the foundation, the assembly process adds crucial functionality by populating all the necessary components. This builds significant value by transforming raw PCBs into functional electronic assemblies.

- It drives efficiency and automation – Automated PCB assembly allows the mass production of electronic products while ensuring speed, repeatability, and quality. It makes the assembly process efficient, consistent, and cost-effective.

Benefits of Outsourcing PCB Assembly

More and more companies are choosing to outsource PCB assembly to external suppliers. Here are some of the major benefits of outsourced assembly services:

- Saves Time and Money – Outsourcing eliminates the need for in-house assembly tools, equipment, and staff. It saves precious time and costs compared to managing assembly internally.

- Access to Advanced Technology – Leading assembly service providers invest heavily in state-of-the-art machinery, tools, and processes. This expertise is used to improve quality and efficiency.

- Skilled Experts – Experienced assembly technicians and engineers provide valuable expertise to build boards accurately and rapidly. They optimize processes through continuous improvement.

- Quality and Reliability – Reputable assembly partners adhere to strict quality standards and certifications. They deliver exceptional quality control and reliable, consistent results.

- Flexibility and Scalability – External assembly resources can be flexibly scaled up or down to match demand fluctuations. This agility allows responding faster to changing market requirements.

- Reduced Risk – Outsourcing transfers assembly risks, equipment maintenance, staffing challenges, etc. to the partner while OEMs can focus on core competencies.

- Faster Time-to-Market – By tapping assembly experts, products can be designed, prototyped, and ramped up faster for accelerated time-to-market.

Leveraging the strengths of an established PCB assembly company maximizes quality, speed, cost efficiency, and overall value. OEMs stand to gain immense benefits through strategic outsourcing.

Parts Sourcing for PCB Assembly

Sometimes, a customer prefers to be responsible for supplying components. This is often the case when using proprietary parts to produce devices for a particular brand or a specific patent.

For many projects, however, clients often prefer to trust our expert assembly teams’ judgment when procuring components. Either approach is OK at JHYPCB, whether a prototype PCB assembly or high volume PCB assembly. JHYPCB can offer full turnkey PCB assembly or partial turnkey PCB assembly services. We’re always happy to produce and assemble PCBs using client-supplied parts, often working under strict NDA conditions as required – but we’re equally comfortable with planning and sourcing the ideal component load-out for you.

With over 10 years of experience in electronic manufacturing services, we’re exceptionally well connected to procurement in today’s fast-moving tech industry supply chain.

The types of electronic components include the following types:

- Passive components

- Connectors

- Terminals

PCB Assembly Methods

Several techniques and methods are used to assemble electronic components onto printed circuit boards. The main PCB assembly methods include:

- Through-Hole Assembly

This traditional method involves inserting component leads through holes drilled in the PCB and soldering them in place on the opposite side. Through-hole components include resistors, capacitors, ICs, transistors, etc. The leads pass completely through the PCB holes, allowing solder to mechanically and electrically connect the components. - Surface Mount Assembly

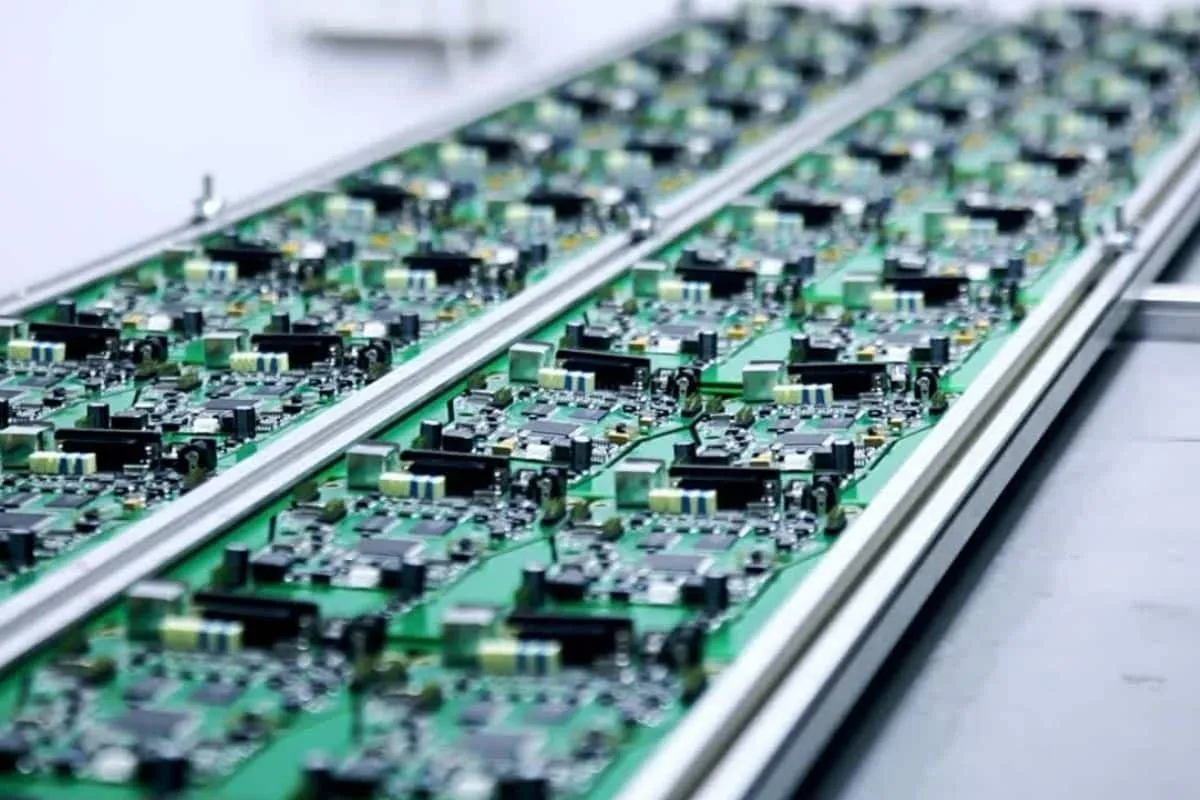

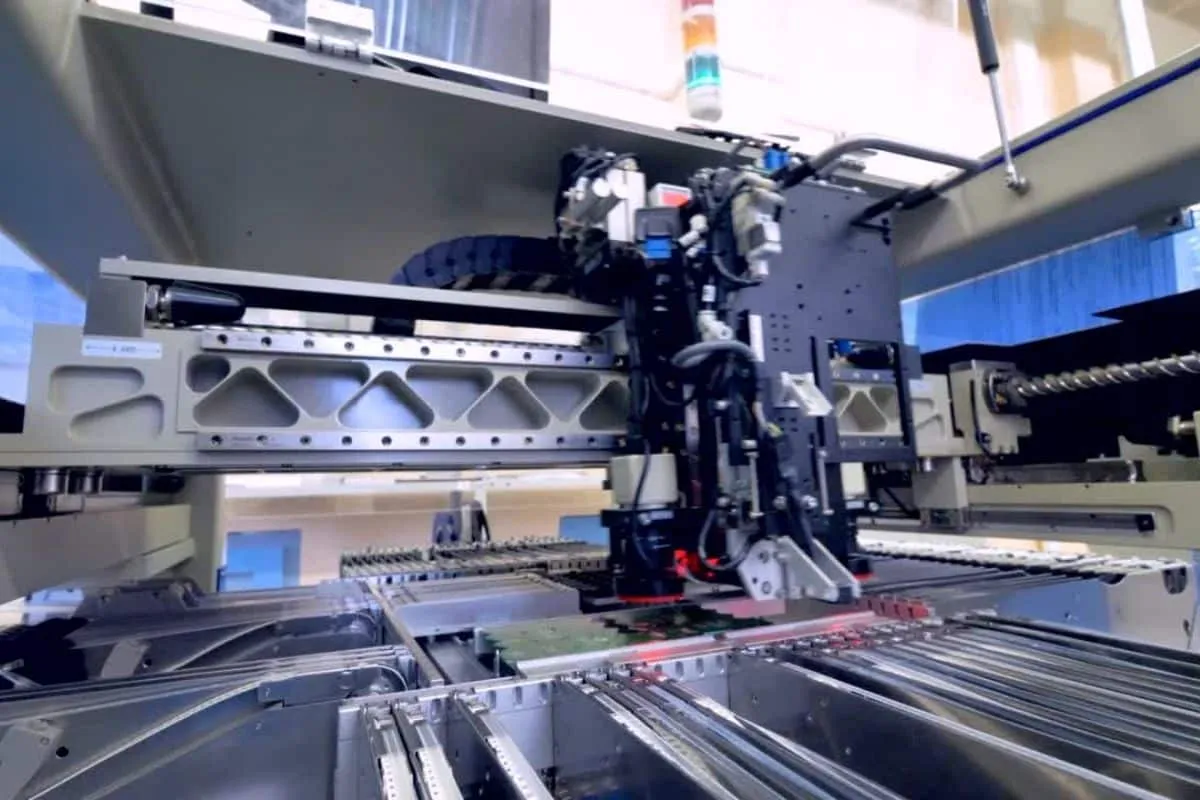

In this process, components are soldered directly onto the surface of the PCB without any leads passing through holes. Surface mount devices (SMDs) like chips are designed with contact pads that align with matching pads on the PCB surface. Reflow soldering melts solder paste to mount components on the board surface. - Automated Assembly

Automated pick-and-place machines and conveyorized soldering systems allow high-volume PCB assembly. Feeders supply components while robotic systems accurately position and solder them onto boards. Automation ensures speed, precision, and consistency. - Manual Assembly

Some complex or low-volume PCBs are still assembled manually. Using tools like soldering irons, tweezers, and microscopes, experienced technicians carefully solder components by hand. The manual assembly allows flexibility and is suitable for prototyping or servicing.

The type of components, production volumes, complexity, accuracy required, budget, and other factors determine the ideal PCB assembly method. A combination of automated and manual techniques may be utilized for optimized results. The right assembly process ensures the completed circuit board’s efficiency, quality, and functionality.

What Mounting Technologies in PCB Assembly?

Once components have been sourced and gathered, the next job is physically mounting everything to the bare PCB board. This phase has three main approaches: Surface Mount Technology (SMT PCB assembly), Through-Hole Technology (THT PCB assembly), or Mixed Technology (SMT & THT).

Each technique has varying benefits for different builds and projects. Whichever method you use will inevitably involve precise, dextrous soldering work to affix your components securely and accurately. This can be achieved either manually or via an automated machining process.

Also, what you need to know is that PCB soldering techniques include wave soldering, reflow soldering, selective soldering, and manual soldering.

JHYPCB can offer Leaded, Lead-free, and RoHS-compliant PCB assembly services.

What Types of PCB Board in PCB Assembly?

JHYPCB’s rich PCB assembly experience can provide you with Rigid PCB, Flexible PCB, Rigid-Flex PCB, and Multilayer PCB assembly services.

The PCB Assembly Process Step-by-Step

PCB assembly is executed through an organized sequence of manufacturing steps to systematically build components onto the boards. Here is a step-by-step breakdown of the standard PCB assembly process flow:

- Sourcing Components

The bill of materials (BOM) lists all the required electronic components. Components conforming to specifications are sourced from approved suppliers.

- Applying Solder Paste

Solder paste is applied on PCB pads using stenciling or printing to provide adhesive and enable soldering.

- Pick and Place Components

Components are accurately picked from reels or trays and robotically placed on the solder paste-coated PCB pads.

- Reflow Soldering

The PCB goes through a reflow oven melting the solder paste to attach components permanently to the board.

- Inspection and Testing

Post-assembly inspection and testing checks for correct assembly, soldering defects, functionality, etc.

- Repairs

Any defective boards or components are repaired or replaced. Boards must pass testing before moving forward.

A protective plastic coating is often applied to shield assembled boards from moisture, dust, etc.

- Final Testing & Certification

Finished boards undergo extensive final testing to verify all specifications are met before delivery.

Proper PCB assembly process control and qualified production staff help assemble high-quality, reliable printed circuit boards.

How to Ensure The Quality of PCB Assembly?

To ensure the quality of products, each PCB assembly company will formulate strict quality control measures. At JHYPCB, we will take the following measures to guarantee that the PCBA delivered to you will surprise you.

PCBA Testing Types

- In-Circuit Test (ICT)

- Functional Test (FCT)

- Burn-In Test

- Severe Conditions Test

- Fatigue Test

- Flying Probe Testing (FPT)

PCBA Inspection Types

What Are The Main Differences Between SMT and THT Assembly?

Surface Mount Technology Assembly involves soldering components in their required locations directly on the bare board’s substrate. Through-hole technology Assembly means passing the conductive ‘legs’ – fine wire leads – of your components through small apertures machined into the substrate at specific points, then soldering them to pads on the reverse face.

- SMT is often preferred for applications that don’t require quite such robust mechanical bonds on the finished PCB.

- It’s a faster process than THT and can be made even more efficient using a Pick And Place PCB assembly machine to accurately arrange all the components before soldering.

- Components designed for SMT layouts are also smaller and cheaper than those made for THT builds. SMT is often more suitable for PCB assembly where low cost and space-saving are a priority, as the components can be arranged at higher densities.

- THT can be ideal when a sturdier physical bond is important at component solder points. Certain types of connectors or hardware devices can benefit greatly depending on their intended application.

- It can take slightly longer to produce a finished circuit board using THT assembly, as additional steps are required at the design and manufacturing stages.

- The actual soldering on a THT-assembled board can again be done manually or automated using a dedicated Insertion Mount Machine.

- Components designed for THT mounting are often more significant and command slightly higher prices than their SMT equivalents. This is partly because they must be produced with the necessary conductive ‘legs’ inserted and secured through the PCB substrate.

Choosing a PCB Assembly Partner

Selecting the right PCB assembly partner is key to achieving high-quality, reliable, cost-effective results. Here are important factors to consider when choosing an EMS provider:

- Technical Capability and Expertise – Look for extensive experience in PCB technologies, assembly methods, miniaturization, density, etc. This shows their ability to assemble complex, quality boards.

- Quality Certifications – Leading firms are certified by ISO 9001 and IATF 16949, indicating adherence to stringent quality management protocols. Review their quality processes.

- Production Capacity and Lead Times – Assess partners’ assembly capacity, flexibility, and ability to meet delivery targets. Ensure they can scale production as per changing needs.

- Location and Logistics – Optimal location and shipping logistics lower costs and delays. Geographic proximity also enables better collaboration.

- Services Offered – For simplified logistics, choose a company offering end-to-end assembly solutions, including sourcing, procurement, testing, repairs, etc.

- Pricing and Contracts – Compare pricing models like per component, per board, or volume-based. Discuss customized contracts clearly outlining terms, IP protection, etc.

- Customer Service – Good partners have customer-focused service with transparent communication and status updates. They proactively resolve issues.

Evaluating PCB assembly partners on these key aspects will help identify the right strategic relationship for the long term.

Conclusion

PCB assembly is an intricate manufacturing process that is truly at the heart of electronics production. It is essential for transforming bare printed circuit boards into fully functioning electronic devices and products by soldering a myriad of components onto the boards. The level of precision and expertise involved in accurately assembling miniature complex components makes it a non-trivial process.

With the right assembly methods, steps, tools and techniques, manufacturers can build quality PCB assemblies cost-effectively and reliably at scale. The rewards of proper PCB assembly are realized through the creation of innovative, cutting-edge electronic products we use everyday. However, the risks of poor assembly include unreliability, performance issues and complete product failures.

By shedding light on what PCB assembly involves, its significance and best practices, we aim to equip PCB designers, engineers and manufacturers with knowledge to optimize this key manufacturing process. Partnering with a qualified, high-capability PCB assembly company provides access to the expertise and technology required to gain a competitive edge. We hope this article serves as a helpful PCB assembly guide as you bring your electronics product ideas to life efficiently.

Related Posts

- Rapid PCB Prototype Assembly Service In China

- How To Order PCB Assembly?

- One-stop PCB Assembly: The Definitive Guide to a Complete PCB Assembly Process

- What is PCB Assembly?

- Types of PCB Soldering Techniques in Assembly Process

- Guide to PCB Assembly Materials

- What are the Advantages of Low Volume PCB Assembly?

- What Constitutes the Cost of PCB Assembly?

- Why Choose China PCB Assembly Manufacturer?