Overview

Before you start a full production run, you would like to create sure that your printed circuit board, or PCB, is functioning properly. Because PCBs are such an integral part of such a big number of electronic devices, if one fails or performs inadequately after full production, it will be extraordinarily costly. Prototyping your PCB beforehand can facilitate your avoiding such a situation. Engineers use prototype PCBs early within the design process to check the functions of a PCB-based solution. They often order multiple runs of prototypes to check redesigns or test one function before moving on to a more complex design. this allows them to find elements that need correction earlier within the process. the sooner you catch those issues, the more cost-effective they’re going to be.

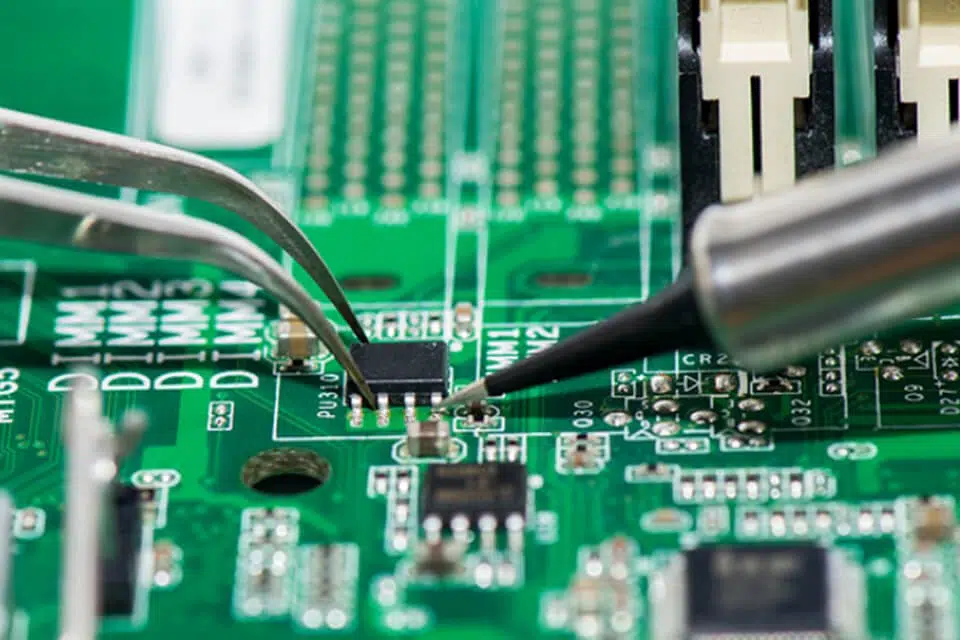

For prototyping your PCB solutions to be effective, you wish an assembler who can quickly create high-quality prototypes that align with how the ultimate product will function as closely as possible. That’s why, at JHYPCB, we provide a quick, accurate prototyping service with a coffee minimum order quantity.

PCB prototypes are early samples of products built with the only real purpose of testing design ideas to determine if they work. Although most prototypes, in general, are made to check basic user functionality, engineers require somewhat, if not entirely, functional PCB prototypes to test the entire functionality of styles. Prototypes offer fewer advanced options and lower production tolerances but will nevertheless be ready to demonstrate whether your designs meet your performance and quality standards.

Benefits of Prototype PCB Assembly

Prototyping is an important stage of the event of your product and employing a PCB manufacturing service for your prototypes can make the method much easier. Once you compare outsourcing the manufacturing to different providers, to working with a specialist PCB company, you’ll find that a prototype PCB manufacturing service is way more convenient, less expensive for initial investments, and also the quality of the merchandise is guaranteed.

There is a variety of benefits of employing a prototype PCB service and OEMs can be cashing in on these. Here are the benefits of employing a prototyping service from JHYPCB.

- Fast Turnaround Time

If you’re searching for the fasted and best rotation times when producing prototypes, then a specialist company can accommodate you. As a specialist PCB company, we understand the stress, and the importance of meeting deadlines, and producing prime quality materials, which is why PCB companies have comprehensive processes in situ to boost manufacturing and production to create it more streamlined. This makes a specialist company more reliable and therefore the right processes can help reduce the lead times.

We can produce PCB prototypes significantly more quickly than we are able to standard production PCBs. We will turn order for prototypes in as little as two days. Our build time for traditional production boards is three to 18 days, while our prototype build time is simply two to 5 days. This quick turnaround means you’ll begin testing new designs more quickly and keep your project moving at a sufficient pace.

- Ability to Detect Flaws Early

Prototyping enables you to catch design flaws early within the development process and before you’ve invested an excessive amount of time and money into the problematic design. Making engineering changes too soon within the process will avoid a spread of potential issues that would impact various areas of your project. Fixing a problem later in the process is more complicated and will be more costly.

- Ability to Test Components Individually

For complex projects that involve multiple PCB-based components, individually testing the various parts is immensely useful. Validating each component individually enables you to pinpoint where any issues may well be occurring. Without this, it’d be difficult to see where the matter was. you’d then must order another whole multi-PCB component or begin to interrupt it down into individual pieces. Doing this from the start of the method is way more efficient.

- Authentic Representation of Standard PCB Performance

Quality PCB prototypes supply an authentic representation of how your last production part will perform. Despite the lower tolerances, they still provide you with an honest idea of what to expect once you begin a regular production run.

- Efficient Project Completion

Using PCB prototypes enables you to identify proper design flaws too soon and quickly pinpoint which components you would like to regulate. Without prototyping, uncovering flaws and therefore the causes of inadequate performance would be rather more time-consuming and will substantially extend a project’s timeframe, potentially leading to lost revenue and dissatisfied customers.

- Reduced Overall Costs

Costs and overheads are always crucial factors when it involves manufacturing prototype circuit boards. After you work with JHYPCB for your prototypes, you will find that your up-front capital investments are drastically reduced. Companies with a limited financial plan may find that working with a professional organization can deliver outstanding flexibility for manufacturing the products. For companies that are looking to manufacture prototypes themselves, they’ll need a big up-front investment to shop for the desired advanced equipment, prime quality materials, and licensed labor, so as to supply top-quality circuit boards.

Prototyping can even reduce the cost of a project, as well. By helping you to catch issues sooner, it enables you to mend them before you invest in an exceedingly high-volume standard production run. By identifying problems in a very simpler version of your product, you’ll be able to rework that simpler component instead of having to supply the whole project, which might be far more expensive.

- Higher Quality Prototypes

JHYPCB have vast experience, industry knowledge, and expertise when it involves manufacturing PCBs. They know all the most recent market developments, trends, and compliance regulations so that they can facilitate you improve the merchandise quality and therefore the time to promote capabilities. Once you work with a prototype PCB manufacturing service, you’ll be cashing in on the advanced CNC machinery, high-quality materials, and expertise when making your prototypes.