“In most cases, the benefits of outsourcing cannot be ignored.”

OEMs increasingly realize the benefits of outsourcing PCB assembly over in-house manufacturing. Outsourcing has become the trend in electronic manufacturing services today. Most printed circuit board manufacturing and printed circuit board assembly are done by third-party companies (i.e., electronic manufacturing service providers).

Electronic manufacturing service providers have factories, experienced electronic manufacturing experts, and qualified employees. In addition to efficient production lines and personnel, they can provide know-how and manufacturing services to companies that need to outsource PCB assembly.

Shorter product lifecycles and technological developments have created new challenges for OEMs in inventory planning and management. Price fluctuations, changes in market demand, design changes, and shorter product lead times all require inventory management expertise that EMS providers can provide to reduce inventory costs.

As your electronic contract manufacturer, JHYPCB is your partner for business success. By outsourcing PCB assembly services to JHYPCB, we will understand your changing needs in a competitive market. Our goal is not only to provide quality and reliable products at competitive prices. We are your outsourcing PCB assembly suppliers, and we are your business partners.

Why do you need to outsource PCB assembly?

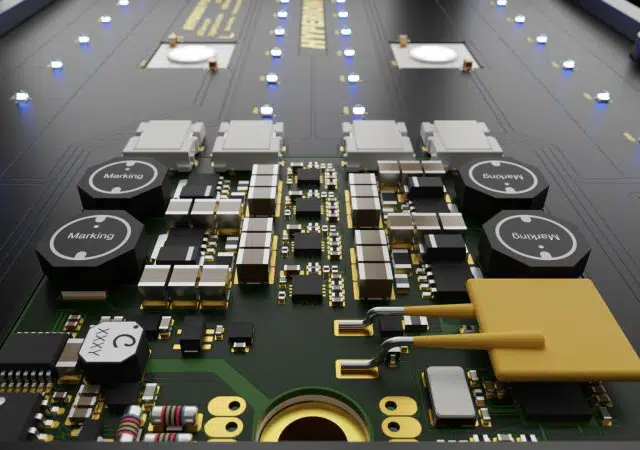

Printed circuit board manufacturing and assembly is one of the main contents of electronic manufacturing services. Printed circuit board assembly is used to produce various electronic product assembly processes. Not so long ago, electronics OEMs used to build PCB assemblies in their factories. However, with the advent of surface mount technology, cutting-edge manufacturing processes, and advanced equipment, PCB assembly production began to be outsourced to specialized contract electronics manufacturers.

These electronic contract manufacturers specialize in PCB assembly, and SMT PCB assembly brings significant benefits to OEMs. OEMs no longer need to invest in equipment and personnel, thus minimizing the cost of each product. The net result of lower unit costs makes OEMs highly competitive in the consumer electronics market.

The benefits of outsourcing PCB assembly

1. Reduce investment costs

Outsourcing PCB assembly to an EMS provider can significantly reduce OEM investment costs. PCB assembly requires a separate area for production while meeting high standards. Because the EMS supplier already has the infrastructure for PCB manufacturing and assembly, OEMs do not need to invest in these infrastructures. Statistics show that you can immediately save 10 to 15 percent by outsourcing PCB assembly to a third-party company.

2. Reduce marginal cost per unit

Because your PCB assembly suppliers focus solely on manufacturing PCB assemblies, they better understand the factors that affect cost-effectiveness in the manufacturing process. This also means they can reduce marginal costs per unit, saving you even more. Lower input costs enable you to deliver end products at competitive prices and maintain your edge in the electronic marketplace.

3. Save Time

Efficient assembly production in a short time. OEMs outsource PCB assembly to contract manufacturers, which can also save a lot of time cost, allowing OEMs to mass-produce PCB assemblies quickly. Because production can be completed in the shortest possible time and efficiencies are achieved, OEMs can quickly introduce their finished electronic products to target markets.

4. Focus on your work

Outsourcing PCB assembly means that you do not need to focus on the process and steps of PCB assembly, and you do not need to have complex and highly specialized PCB assembly knowledge and skills.

Time may be your first profit from working with a PCB assembly manufacturer. Free yourself from these time-consuming tasks, and you’ll have more time and energy to develop new products and services and more time and energy for marketing and advertising.

5. Better supply chain management

As we all know, the success of PCB assembly depends not only on infrastructures, such as mechanical equipment, personnel, and process capabilities. Of course, these are all necessary factors, but they are not enough. To ensure the project’s success, it is also necessary to ensure that the supply of electronic components can be delivered on time. Rising material prices and uncertainty about market shortages add to the financial risk.

PCB assembly suppliers all have a complete supply chain management system. These outside assembly suppliers can take responsibility for all the individual components of the supply chain and relieve OEMs of these complex tasks.

6. High-quality products

The professional skills and rich experience of outsourcing service providers of PCB assembly virtually improve the quality of PCB assembly.

Electronic contract manufacturers are equipped with ISO certificates and IPC standards. Contract PCB assembly manufacturers have strict quality control procedures, which provide good value for money.

7. PCB Assembly Inspection and Testing

PCB assembly manufacturers have comprehensive quality control procedures, including PCB assembly inspection and testing. They can identify issues you didn’t detect (such as design flaws, materials, etc.) before the product goes to market. This is because the wealth of experience gained over the years has made them experts at what they do.

8. Flexibility

The PCB assembly outsourcing service provider offers a high degree of flexibility to the companies that use it. Service providers can precisely tailor their service offerings to their customers’ needs.

Subcontracting areas in PCB assembly are entrusted to suppliers who evolve following the principles of a competitive market to respond to customer needs, looking for competitiveness, quality, and service optimization. Using the experience of a contractor who perfectly knows the realities of the market, OEMs have a chance to escape stiffness and routine. Furthermore, they have the opportunity to benefit from contractual cooperation, which is, by nature, more dynamic and adaptive.

9. Increase productivity

EMS providers undertaking PCB assembly have a more robust production capacity and resources (including human resources) and can plan production more flexibly and dynamically.

10. Support in new product introduction (NPI)

The support of your EMS proves invaluable during the NPI process. One of the benefits of outsourced manufacturing is that experienced contractors can provide appropriate advice on DFM to verify that the product is designed for mass production.

11. No MOQ

Some outsourced PCB assembly manufacturers do not have MOQ requirements; they don’t care if you need a small number of dozens or a large number of tens of thousands of PCB components.

A good EMS assists its clients in the production of high-mix low-volume (HMLV) PCB assembly series, which typically range from tens to hundreds of product versions and/or configurations, production batches of 1 to 1000 pieces, and production of low-volume high-mix (LMHV) PCB assembly series, which range from thousands to tens of thousands of pieces.

12. After-sales and other additional services

A good EMS has a team of experienced experts who can support you at every stage of the product life cycle, advise on design for manufacturability during the design phase, or help with the production of the prototype.

The EMS provider can also provide support after your product is on the market. It can help analyze user-reported failures, so you can understand how quickly and where the product is damaged in actual use.

13. A healthy partnership

Great contract manufacturers want you to be successful and potentially your long-term partner. They can help you with all aspects of your business, including the design of your PCB layout and sometimes even the distribution process. In conclusion, a good business partner is always your valuable asset.

Common mistakes to avoid when outsourcing PCB assembly

Now that you have fully understood and considered the benefits of outsourcing PCB assembly, you have decided to start your search for the proper electronics contract manufacturer. However, there are some common mistakes to avoid when sourcing and outsourcing:

- Rushing your decision

- Poor communication

- Trust issues

- Choosing the lowest rates

Grow your business by partnering with a PCB assembly supplier

It is a win-win option for an OEM to outsource PCB assembly to an electronics manufacturing service provider.

Have you decided to start outsourcing your PCB assembly? If so, please get in touch with us for reliable and quality PCB assembly outsourcing services. We have 11 years of electronic manufacturing service experience, and we have the certification to ensure our products are safe and reliable.