Importance of PCB Assembly in Various Industries

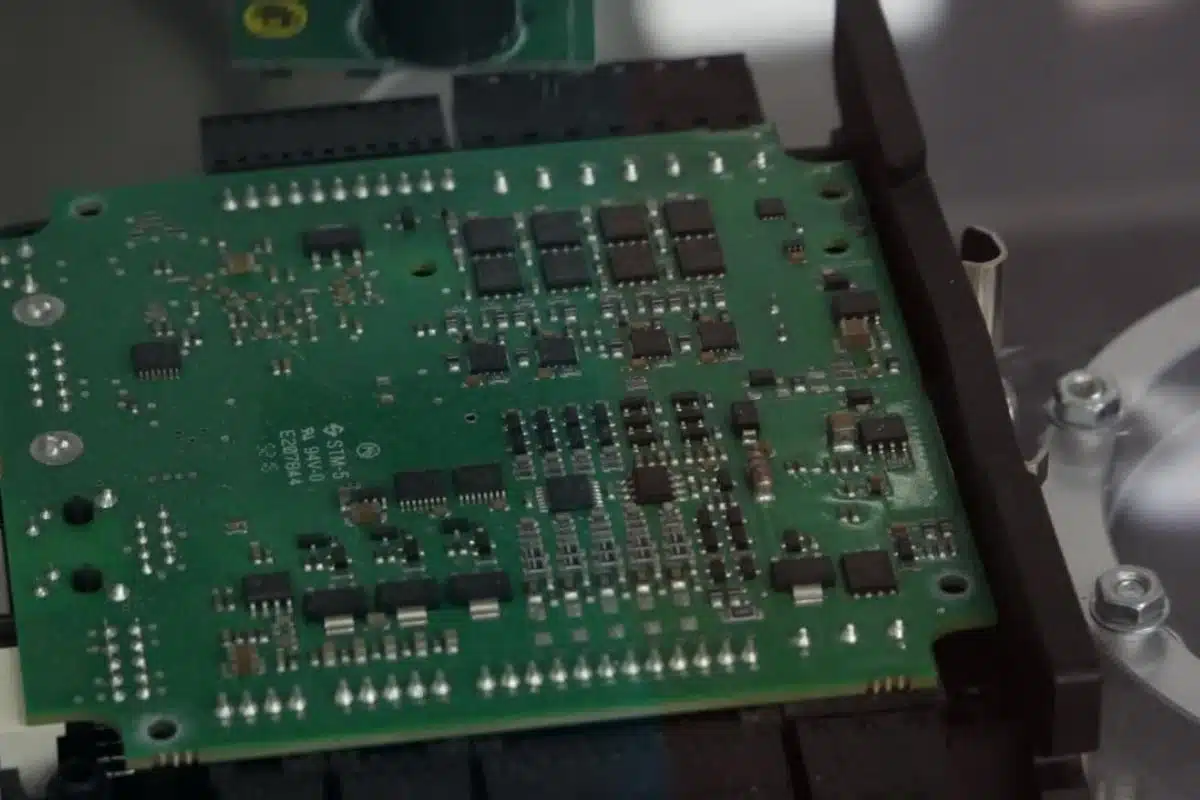

PCB assembly is a crucial process in the electronics manufacturing industry. It involves soldering and assembling various electrical and electronic components onto a PCB to form a functional electronic circuit. From the smallest embedded systems to high-end computers, nearly every electronic device relies on PCB assembly during production. PCB assembly application spans diverse industries, including consumer electronics, automotive, aerospace, medical devices, and more.

As electronics have evolved over the years, so too have the techniques and technologies for assembling them. PCB assembly methods have advanced significantly, enabling more compact, higher performance, and more reliable electronic circuit designs. Miniaturization, automation, and innovations such as HDI and flexible PCBs are some of the key trends shaping PCB assembly today. These developments allow PCB assembly to adapt to the needs of cutting-edge electronic devices and products.

This blog post will take a closer look at how PCB assembly is utilized across major industries. We will also highlight some recent advancements in PCB assembly processes and technologies that drive innovation across electronics manufacturing. Understanding the applications and evolution of PCB assembly provides key insights into the foundations behind modern electronic product development and production.

PCB Assembly in Consumer Electronics

PCB Assembly plays a critical role in the manufacturing of consumer electronic devices. From smartphones to home appliances, PCB Assembly is an essential process that ensures the functionality and reliability of these devices.

Examples of Consumer Electronic Devices that use PCB Assembly

Consumer electronic devices that use PCB Assembly are numerous and include:

Smartphones: Almost all contemporary smartphones rely heavily on PCB Assembly technology, with multiple PCBs used in each device.

Laptops and Tablets: These devices require high levels of precision and accuracy, which can only be achieved through quality PCB Assembly services.

Gaming Consoles: PCB Assembly technology makes gaming consoles compact, lightweight, and energy-efficient.

Home Appliances: Many modern home appliances, such as washing machines, refrigerators, and air conditioners, utilize PCB Assembly technology to provide reliable and efficient operation.

Advancements in PCB Assembly Technology for Consumer Electronics

With the increasing demand for smaller and more sophisticated electronic devices, PCB Assembly technology has advanced significantly to meet these demands. Some of the notable advancements in PCB Assembly technology for consumer electronics include:

Surface Mount Technology (SMT): SMT is a widely used PCB Assembly technology that allows for smaller, more compact PCB designs.

3D Printing: 3D printing technology has enabled the production of customized PCBs, thus improving the efficiency and speed of the manufacturing process.

Miniature Components: The development of miniature electronic components has enabled the manufacturing of smaller and more powerful electronic devices.

High-Speed PCB Design: Advanced PCB design software has made it possible to design high-speed PCBs that meet the performance requirements of modern consumer electronic devices.

In conclusion, PCB Assembly technology is indispensable to the consumer electronics industry. It enables the production of highly functional and reliable electronic devices essential in our daily lives. As such, the continued advancement of PCB Assembly technology is crucial to meet the ever-increasing demands of the consumer electronics industry.

PCB Assembly in Automotive

The automotive industry relies heavily on PCB assemblies and has been one of the major adopters of PCB technology over the past decades. Within automobiles, PCB assemblies can be found in virtually every electronic system and component.

Some of the most common automotive applications of PCB assembly include:

- Engine control units – The engine control unit (ECU) is the core computer that manages engine performance, emissions, and other vital functions. PCB assemblies enable the circuitry and intelligence of ECUs.

- In-vehicle infotainment – The infotainment systems consisting of audio, video, navigation, and connectivity functions depend on complex PCB circuitry. PCB assembly allows for the integration of processors, memory, wired and wireless connectivity, and multimedia interfaces.

- Advanced driver-assistance systems (ADAS) – ADAS technologies, such as blind spot detection, parking assistance, collision avoidance, etc., utilize PCB assemblies for radar, camera, and sensor circuitry.

- Lighting systems – Interior and exterior vehicle lights and signaling require PCBs for control and connectivity.

- Battery management systems – PCB assemblies are critical for battery pack control and monitoring in hybrid and electric vehicles.

With the accelerating development of autonomous and connected vehicles, PCB assembly applications in automotive are also evolving. Self-driving vehicle technologies rely heavily on PCB implementations due to their circuit density and reliability advantages. PCB assembly supports autonomous vehicle systems’ computational power, signal integrity, and data bandwidth. Continued PCB assembly innovations will be a key enabler for the future of smart, self-driving cars.

PCB Assembly in Industrial Control

PCB Assembly is widely used in the manufacturing of industrial control equipment. These devices are used in various industries, such as automation, robotics, and power generation. PCB Assembly technology plays a crucial role in providing the necessary precision, reliability, and durability that these devices require.

Examples of Industrial Control Equipment that use PCB Assembly

Industrial control equipment that utilizes PCB Assembly technology includes:

Robotics: PCB Assembly technology is used in manufacturing industrial robots, providing them with the necessary precision and accuracy required for their operations.

Automation Systems: Automated production lines use sensors, controllers, and actuators that rely on PCB Assembly technology for reliable and accurate operation.

Power Generation Equipment: Modern power generation equipment such as wind turbines, solar panels, and hydroelectric generators rely heavily on PCB Assembly technology for efficient and reliable operation.

Medical Devices: Many medical devices, such as imaging systems, surgical tools, and patient monitoring devices, use PCB Assembly technology for precise and reliable operation.

Advancements in PCB Assembly Technology for Industrial Control

To meet the demands of the industrial control industry, PCB Assembly technology has advanced significantly in recent years. Some of the notable advancements include:

High-Density Interconnect PCBs: HDI PCBs enable the manufacture of compact and lightweight industrial control devices, making them more energy-efficient and cost-effective.

Through-Hole Assembly: Through-hole assembly technology allows for mounting larger components on the PCB, providing more robust and durable industrial control devices.

Multilayer PCBs: Multilayer PCBs provide improved signal integrity and reduce electromagnetic interference in industrial control devices.

Advanced Testing and Inspection: Advanced testing and inspection technologies such as X-ray and automated optical inspection ensure the reliability and quality of industrial control devices.

PCB Assembly in IoT

IoT devices rely heavily on PCB Assembly technology for compact size, low power consumption, and wireless connectivity. Using PCB Assembly in IoT devices has enabled the creation of smart and interconnected systems that provide reliable and seamless data communication.

How IoT Devices Utilize PCB Assembly

IoT devices such as wearables, sensors, and smart home devices use PCB Assembly technology to provide various functionalities such as:

Wireless Connectivity: IoT devices utilize PCB Assembly technology to provide wireless connectivity options such as Wi-Fi, Bluetooth, and cellular networks.

Low-Power Consumption: IoT devices require minimum power consumption for long battery life. PCB Assembly technology uses advanced power-saving techniques to achieve this requirement.

Compact Size: IoT devices must be small and lightweight to facilitate portability and integration into various applications. PCB Assembly technology provides a means to create highly dense PCBs with reduced form factor.

Sensor Integration: IoT devices rely on sensors to collect data from the environment. PCB Assembly technology enables the integration of these sensors onto the PCBs, reducing the device’s overall size and complexity.

Advancements in PCB Assembly Technology for IoT

The development of IoT technology has led to significant advancements in PCB Assembly technology. Some notable advancements include:

Flexible PCBs: Flexible PCBs allow for the creation of bendable and foldable IoT devices, enabling them to conform to different shapes and sizes.

High-Frequency PCB Design: High-frequency PCB design enables the creation of IoT devices that operate at higher frequencies, improving their performance and reliability.

Miniaturization: The miniaturization of electronic components has created smaller and more powerful IoT devices.

Advanced Testing and Inspection: Advanced testing and inspection technologies ensure the quality and reliability of IoT devices, reducing the risk of system failure.

PCB Assembly in Medical Devices

PCB assembly is ubiquitous in medical devices and instrumentation due to the technology’s reliability, customization, and miniaturization advantages. Some major examples include:

- Hearing aids – Modern hearing aids rely on ever-shrinking PCB assemblies to integrate microphone, amplifier, speaker, and signal processing components into tiny wearable devices. PCBs make hearing aid circuitry more powerful while fitting in the ear canal.

- Pacemakers – Implantable pacemakers use rigid-flex PCBs to incorporate timing/control circuitry and batteries into a compact, biocompatible package. Careful PCB assembly allows pacemakers to operate reliably within the human body for years.

- Blood glucose meters – Portable glucose meters use PCB assemblies tailored to integrate test strip connectors, processor controls, display, and data storage in a handheld device.

- Medical imagers – X-ray, MRI, and other medical imaging modalities utilize specialized PCBs to operate high-speed sensors, switches, and detectors under demanding conditions.

- Surgical tools – Many digitally-assisted surgical tools rely on PCB assemblies for integrating sensors, cameras, motors, and haptics into ergonomic designs.

- Wearable health trackers – Smartwatches and fitness bands leverage PCB assembly to cram multiple sensors, batteries, and antennas into sleek, aesthetically-designed packages.

With the growth of digital health and personalized medicine, PCB assembly will continue playing an indispensable role in enabling sophisticated, miniaturized, and reliable medical devices.

PCB Assembly in Aerospace and Defense

PCB assembly is mission-critical for aerospace and defense systems that operate under extreme mechanical, thermal, and radiation conditions. Some examples include:

- Guidance systems – Inertial guidance systems, GPS receivers, and other navigation electronics utilize multilayer PCBs to integrate precise signal processing and control circuitry.

- Avionics – Flight control computers, collision avoidance radar, and other avionics heavily rely on rigid, high-frequency PCB assemblies due to size, weight, and reliability requirements.

- Satellites – Space’s harsh vacuum and temperature swings necessitate highly durable PCB assemblies for satellites.

- Missile control systems – Missile guidance electronics demand tiny, hardened PCBs that withstand g-forces and vibration during launch and flight.

- Radar and communication systems – Military radar and radio communication infrastructure leverages specialty PCB materials like PTFE to function reliably in all environments.

- Wearable systems – Helmet-mounted displays, wrist commanders, and exoskeleton controls benefit from PCB integration and miniaturization.

PCB assembly for aerospace and defense pushes the envelope regarding high-density interconnects, thermal management, and mechanical performance. Continued research into high-reliability space-rated and ruggedized PCB technology will support next-gen aerospace accomplishments and robust defense systems.

PCB Assembly in Smart Home

PCB Assembly technology plays a significant role in manufacturing smart home devices. These devices use advanced PCB Assembly technology to provide reliable and seamless connectivity, automation, and control.

Examples of Smart Home Devices that use PCB Assembly

Smart home devices that utilize PCB Assembly technology include:

Smart Lighting Systems: Smart lighting systems use PCB Assembly technology to provide wireless connectivity, allowing users to control light settings remotely.

Smart Thermostats: PCB Assembly technology is used in smart thermostats to enable energy-efficient temperature control and remote access through mobile applications.

Home Security Systems: Many home security systems use PCB Assembly technology to provide wireless connectivity, motion detection, and video surveillance functions.

Smart Locks: Smart locks use advanced PCB Assembly technology to provide secure and convenient home access control through wireless connectivity.

Advancements in PCB Assembly Technology for Smart Homes

To meet the demands of the smart home industry, PCB Assembly technology has advanced significantly in recent years. Some notable advancements include:

IoT Integration: Integrating IoT technology into smart home devices allows for interconnected systems that provide seamless and automated control over various home functions.

HDI PCBs: HDI PCBs allow for the creation of compact and lightweight smart home devices, reducing their form factor and increasing energy efficiency.

Wireless Connectivity: Advanced PCB Assembly technology provides multiple wireless connectivity options such as Wi-Fi, Bluetooth, and Zigbee, enabling seamless and reliable communication between smart home devices.

Energy Harvesting: Energy harvesting technology enables smart home devices to generate and store energy, reducing reliance on external power sources.

Recent Advancements in PCB Assembly

Along with evolving applications across industries, the technology behind PCB assembly itself has advanced considerably in recent years. Some key trends and innovations in PCB assembly include:

- Miniaturization

As electronic devices shrink in size, so must their circuit boards. PCB miniaturization has been made possible through smaller components, higher-density interconnects, and advanced fabrication techniques enabling tighter tolerances, fine features, and thinner materials. These assembly advances allow more functionality to fit within tiny form factors.

- HDI PCBs

High-density interconnect PCBs integrate microvias and dense component packing to optimize circuit density. HDI technologies like sequentially laminated multilayering supports the needs of miniaturized consumer and industrial electronics with their ability to interconnect hundreds of signals across compact PCBs.

- Flexible/Rigid-Flex PCBs

Flexible PCBs allow circuits to bend and contour within products, while rigid-flex combines stiff printed board sections with flexible interconnects. Flexible assembly opens up wearables, medical devices, robotics, consumer gadgets, and more applications.

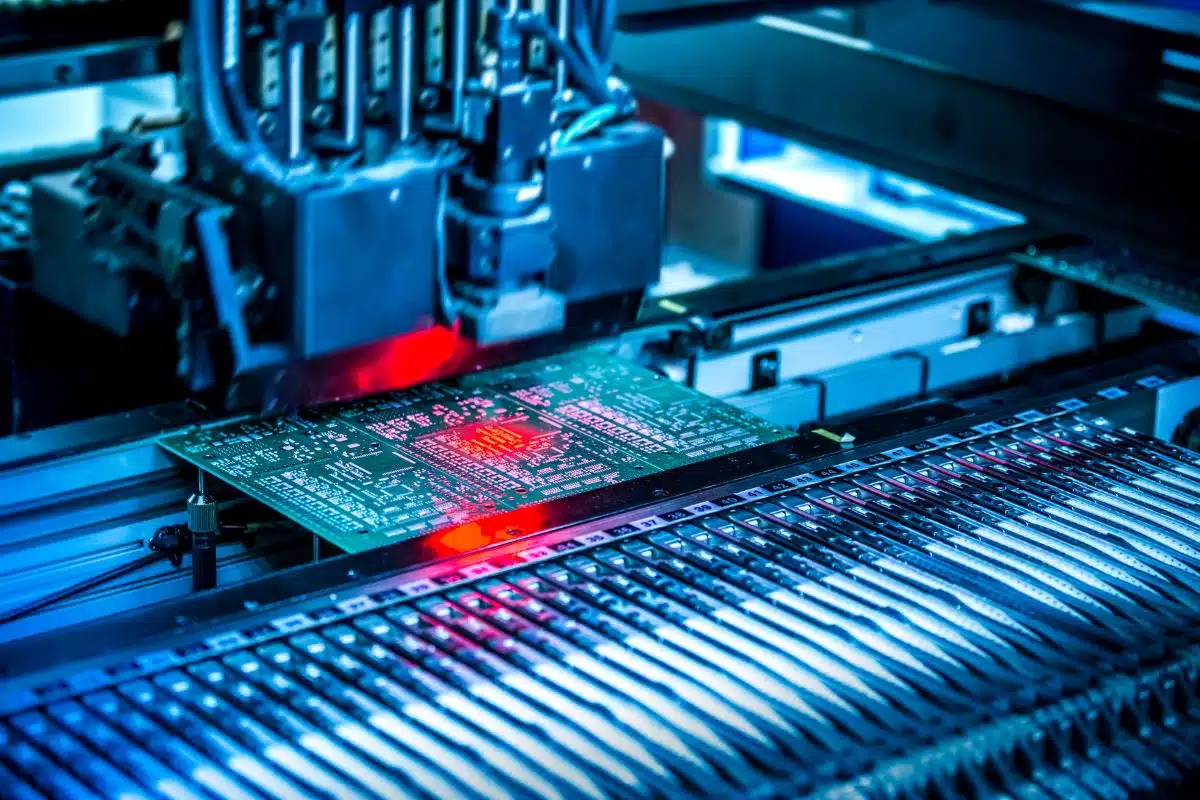

- Automation

Automated assembly systems like surface mount technology pick-and-place machines, solder paste screening, and assembly optimization software have maximized PCB assembly speed, precision, and efficiency. Continued automation through robotics and AI promises to unlock greater quality and output.

These PCB assembly innovations will expand the possibilities for sophisticated and compact electronics across all tech sectors.

Conclusion

In conclusion, PCB Assembly technology is critical in various industries, including consumer electronics, industrial control, IoT, and smart homes. The wide range of applications for PCB Assembly services highlights its importance in manufacturing electronic devices.

JHYPCB is a leading PCB assembly manufacturer based in China, providing high-quality prototype PCB assembly, quick-turn PCB assembly, and turnkey PCB assembly services. With years of experience in the industry, JHYPCB offers reliable and efficient solutions for assembling printed circuit boards for various applications.

The advancements in PCB Assembly technology have made it possible to manufacture more compact, energy-efficient, and reliable electronic devices that meet the demands of modern society. These advancements include high-density interconnect PCBs, flexible PCBs, miniature components, and advanced testing and inspection technologies.

As such, PCB Assembly services ensure electronic devices’ smooth operation and productivity across various industries. With its advanced technology and experience in the field, JHYPCB is well-positioned to provide quality PCB Assembly services to customers worldwide.